The sequencing batch reactor (SBR) is a discontinuously operating system for the biological treatment of wastewater. In contrast to continuously operating systems such as classic activated sludge processes, the SBR combines all process steps - from filling to secondary clarification - in a single reactor tank. The process is particularly flexible and is used in both municipal and industrial wastewater treatment.

Table of contents

Importance and advantages of the SBR system

Process integration:

- The SBR combines several treatment stages (aeration, sedimentation, clear water removal) in one tank, which saves space and costs.

Flexibility:

- The process can be adapted to different wastewater compositions and load fluctuations, making it ideal for industrial applications.

High cleaning performance:

- The SBR enables the effective removal of organic substances (BOD/CSB), nitrogen (nitrification/denitrification) and phosphorus (biological or chemical precipitation).

Modularity:

- The system can be easily scaled and is therefore suitable for small systems as well as large-scale applications.

How the sequencing batch reactor works

The operation of an SBR takes place in several successive phases. Each phase fulfills a specific function in the cleaning process:

1st filling phase

- Purpose:

- Discharge of raw wastewater into the reactor.

- Details:

- During filling, the wastewater is mixed with the existing biomass (activated sludge).

- Depending on the process requirements, filling can be static (without mixing) or dynamic (with aeration).

- Optimization:

- Dynamic filling improves the pre-removal of easily degradable organic substances and promotes denitrification (nitrogen removal).

2nd reaction phase

- Purpose:

- Biological degradation of organic and inorganic impurities.

- Details:

- Aeration: Oxygen is supplied via diffusers or surface aerators to activate aerobic microorganisms.

- Nitrification: Ammonium (NH₄⁺) is converted into nitrate (NO₃-) by nitrifying bacteria.

- Denitrification: In anoxic phases (without oxygen supply), nitrate is reduced to nitrogen gas (N₂) by heterotrophic microorganisms.

- Phosphorus elimination:

- Biological: Promotion of polyphosphate-accumulating organisms (PAOs) through targeted control of aerobic and anoxic phases.

- Chemical: Precipitation with iron or aluminum salts.

- Optimization:

- Precise control of the aeration phases allows the cleaning performance to be adapted to specific parameters.

3rd sedimentation phase

- Purpose:

- Separation of the biomass (sludge) from the purified water.

- Details:

- The reactor is hydraulically relieved so that the biomass can sink.

- Sedimentation takes place under calm conditions in order to avoid resuspension of the sludge.

4. clear water removal phase

- Purpose:

- Discharge of the clarified water from the upper area of the reactor.

- Details:

- Extraction takes place via a height-adjustable clear water outlet or a special extraction device.

- The clarified water is either discharged directly or fed to a further treatment stage.

5. excess sludge discharge

- Purpose:

- Regular removal of biomass to maintain the desired sludge load (F/M ratio) in the reactor.

- Details:

- The excess sludge is removed and usually sent for sludge treatment.

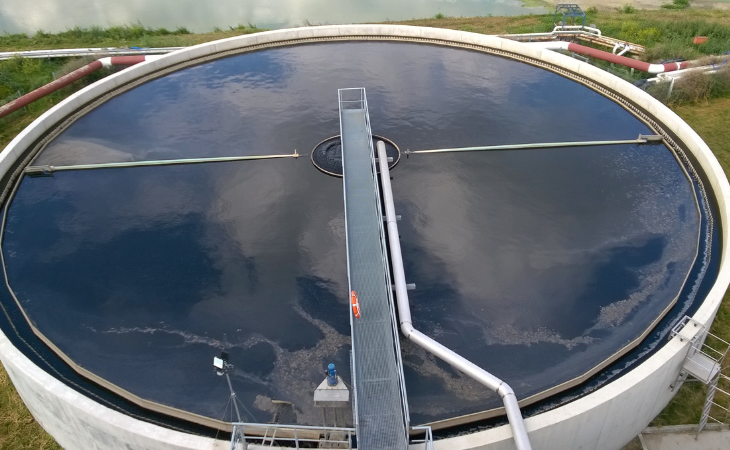

Photo: SBR reactor as part of the ALMA BHU BIO system

Technical features of the SBR

reactor volume:

- The volume of the reactor is determined by the feed quantity and the retention time.

- Typical dwell times: 6-12 hours (depending on the load and requirements).

Ventilation systems:

- Use of fine-bubble diffusers or surface aerators.

- Control via oxygen sensors to optimize energy consumption.

control system:

- The SBR requires a precise automated control system that regulates the phases and aeration intervals.

- Sensors monitor parameters such as oxygen concentration, ammonium, nitrate and redox potential.

Sludge load (F/M ratio):

- The ratio of load (F) to biomass (M) is typically between 0.1 and 0.4 kg BOD/kg DM-d.

Advantages of the SBR system

- High flexibility:

- Adaptation of the phases to different wastewater compositions and loads.

- Compact design:

- No separate secondary clarifier required.

- High cleaning performance:

- Effective nitrogen and phosphorus elimination through targeted process control.

- Energy efficiency:

- Demand-based ventilation reduces energy consumption.

Disadvantages and challenges

- High control effort:

- Phase control requires a complex automation system.

- Fluctuations in inflow:

- The cleaning performance may be impaired during sudden load peaks.

- Pulsating wastewater discharge:

- The purified water is not discharged continuously, but in batches, which requires buffering in the downstream treatment.

Optimization options

- Sensor integration:

- Use of ammonium and nitrate probes for dynamic control of the aeration phases.

- Phase adjustment:

- Extension of the anoxic phases for improved denitrification.

- Modular extension:

- If loads increase, additional reactors can be connected in parallel.

Conclusion

The sequencing batch reactor (SBR) is a highly efficient and flexible system for biological wastewater treatment that is particularly suitable for applications with fluctuating feed conditions. Thanks to its compact design and the possibility of precise control, the SBR offers considerable advantages over conventional continuous systems. With state-of-the-art sensor technology and automation, the SBR process can be optimally adapted to specific requirements and thus makes a significant contribution to sustainable water and wastewater treatment.

For further information on our products, please feel free to contact us at any time!