A SBR reactor (Sequencing Batch Reactor) is a discontinuously operated biological purification process that integrates several treatment steps in a single tank. The SBR reactor is often used in water and wastewater treatment to remove organic compounds, nitrogen and phosphorus. By sequencing different phases in a single reactor, this system offers a flexible and space-saving alternative to continuous processes.

Table of contents

Structure of an SBR reactor

Reactor vessel:

- A central container in which all process phases take place. It can be rectangular or round and is often made of concrete, steel or plastic.

Ventilation system:

- Fine-bubble diffusers or surface aerators supply the reactor with oxygen during the aerobic phases.

- The oxygen supply is regulated by sensors and control systems.

Mixing system:

- Mechanical agitators or flow pumps ensure homogeneous distribution of the wastewater and biomass during the anoxic phases.

Clear water outlet:

- A height-adjustable outlet or a special clear water removal device removes the purified water from the upper section of the reactor after sedimentation.

Automation:

- Modern SBR reactors have a comprehensive control system that coordinates the individual phases, aeration and sensor monitoring.

How the SBR reactor works

The SBR reactor operates in a cyclical mode in which different phases are run through one after the other. This temporal separation makes it possible to combine several processes in a single reactor.

1st filling phase

- The raw wastewater is fed into the reactor and mixed with the existing biomass (activated sludge). Filling can be static or dynamic (with aeration).

- Objective: Discharge of wastewater and start of biological processes.

2nd reaction phase

- During this phase, the pollutants are biodegraded:

- Aerobic conditions: Oxygen is supplied to break down organic matter and oxidize ammonium to nitrate (nitrification).

- Anoxic conditions: Without oxygen supply, microorganisms use nitrate as an electron acceptor to form nitrogen gas (denitrification).

- Phosphorus elimination: Either biologically by polyphosphate-storing organisms or chemically by adding precipitants.

- Objective: Removal of carbon compounds, nitrogen and phosphorus.

3rd sedimentation phase

- Once the biological processes are complete, the aeration is stopped so that the biomass can settle at the bottom of the reactor.

- Objective: Clarification of the water by separating sludge and clear water.

4. clear water removal phase

- The clarified water is removed from the upper section of the reactor. This is done carefully so as not to stir up any particles from the sediment layer.

- Objective: Removal of the purified water.

5. sludge discharge

- Excess biomass is periodically removed to maintain the desired sludge age and reactor performance.

- Objective: Regulation of the biomass concentration in the reactor.

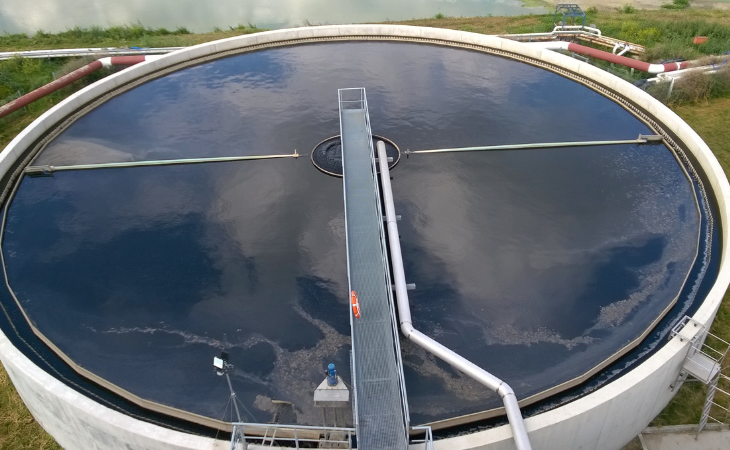

Photo: SBR reactor as part of the ALMA BHU BIO system

Technical features of the SBR reactor

Cycle times:

- A complete cycle typically takes between 6 and 12 hours, depending on the wastewater load and cleaning requirements.

Sludge load:

- The ratio of load (F) to biomass (M) is typically between 0.1 and 0.4 kg BOD/kg DM-d.

Ventilation control:

- The oxygen supply is monitored by sensors for oxygen, ammonium and nitrate and controlled as required.

Capacity:

- SBR reactors can be designed for small to large volume flows, making them suitable for both municipal and industrial applications.

Advantages of the SBR reactor

High process flexibility:

- Adaptation of the operating phases to different wastewater compositions.

Compact design:

- No separate secondary clarifier required, which saves space and construction costs.

High cleaning performance:

- Effective removal of carbon, nitrogen and phosphorus through precise control of the reactor conditions.

Energy efficiency:

- Demand-based ventilation minimizes energy consumption.

Modularity:

- Easy to expand by operating several reactors in parallel.

Disadvantages of the SBR reactor

Complex control:

- Operation requires a precise automation system to control the phase sequence.

Discontinuous operation:

- Purified water is not discharged continuously, but in batches, which requires buffering in the downstream treatment.

Fluctuations in inflow:

- Sudden load peaks can impair the cleaning performance if no buffer tanks are available.

Optimization potential for the SBR reactor

Sensor integration:

- Use of ammonium, nitrate and redox sensors to improve phase control.

Dynamic control:

- Automatic adjustment of the cycle times to the actual load.

Hybrid solutions:

- Combination with other processes such as membrane bioreactors (MBR) to increase purification performance and capacity.

Conclusion

The SBR reactor is an extremely flexible and efficient system for biological wastewater treatment. Thanks to its ability to integrate different treatment stages in a single tank, it offers a space-saving and cost-effective solution for municipal and industrial applications. The high purification performance and adaptability to different wastewater compositions make the SBR reactor a future-proof technology in water and wastewater treatment. With modern automation and intelligent control, the potential of this process can be further maximized, especially in complex industrial applications.

For further information on our products, please feel free to contact us at any time!