Polyvinyl chloride (PVC) is a thermoplastic produced by the polymerization of vinyl chloride monomers (VCM). Due to its versatile properties, such as chemical resistance, good mechanical stability and cost-effective processing, PVC is a commonly used material in industrial water and wastewater treatment. It is used in a variety of applications, including piping systems, fittings, tanks and protective coatings.

Table of contents

Chemical and physical properties of PVC

PVC is a halogenated plastic that can be adapted to specific requirements by adding plasticizers, stabilizers or fillers. There are two main types: rigid PVC (PVC-U) and plasticized PVC (PVC-P).

1. material structure

- PVC consists of polymerized vinyl chloride molecules. Its chemical formula is [CH2–CHCl]n\text{[CH}_2\text{–CHCl]}_n[CH2-CHCl]n.

- The chlorine atoms in the molecular structure give PVC its high flame retardancy and chemical stability.

- PVC is a naturally brittle material, but is made flexible by plasticizers.

2. variants of PVC

- Rigid PVC (PVC-U):

- Without plasticizers.

- High strength and resistance to chemicals.

- For use in pipes, tanks and fittings.

- Soft PVC (PVC-P):

- Contains plasticizers that increase flexibility.

- Use in flexible hoses and seals.

- Chlorinated PVC (PVC-C):

- Increased chlorination improves temperature and chemical resistance.

- For use at temperatures up to 90 °C.

3. mechanical and chemical properties

Chemical resistance:

- Excellent against acids, alkalis, alcohols and salts.

- Restrictions: Not resistant to aromatic and chlorinated solvents.

Temperature resistance:

- PVC-U: -15 °C to 60 °C.

- PVC-C: Up to 90 °C.

Mechanical properties:

- High rigidity and compressive strength (with PVC-U).

- Flexibility and tear resistance (for PVC-P).

Flame retardant:

- Self-extinguishing on contact with fire due to the high chlorine content.

Density:

- Moderate: 1.35-1.45 g/cm³, depending on fillers and additives.

UV resistance:

- Without the addition of stabilizers, PVC is not UV-resistant and can become brittle.

Photo: Our ALMA NeoDAF HD flotation system for small wastewater streams with PVC reaction loop

PVC manufacturing process

PVC is produced by polymerizing vinyl chloride monomers (VCM). Different types of PVC are produced depending on the polymerization method:

Suspension polymerization:

- Most frequently used method.

- Produces PVC with a uniform particle size, ideal for molded parts and pipes.

Emulsion polymerization:

- Results in finely divided PVC, which is used for coatings and flexible products.

Mass polymerization:

- Direct polymerization without solvents, ideal for pure PVC.

Additives:

- Plasticizers: Increase flexibility.

- UV stabilizers: Improve weather resistance.

- Flame retardants: Reduce flammability.

Applications of PVC in water and wastewater treatment

PVC is one of the most commonly used materials in water and wastewater technology. Its versatility allows it to be used in various components and systems.

1. pipelines and fittings

- Application:

- PVC-U pipes for drinking water, waste water and chemical transportation.

- For use in gravity and pressure lines.

- Advantages:

- High chemical resistance to waste water and cleaning chemicals.

- Low flow resistance due to smooth inner surfaces.

- Simple connection by gluing or push-fit sockets.

- Technology:

- Bonding technology: Use of PVC adhesives for tight connections.

- Flange systems: Suitable for larger pipe diameters.

2. coatings and linings

- Application:

- Protective coatings for metals and concrete in corrosive environments.

- Use in sewage treatment plants and chemical storage tanks.

- Advantages:

- Prevents corrosion and increases the service life of the systems.

3. hoses and seals

- Application:

- Flexible PVC hoses for process water and waste water.

- Sealing profiles in piping systems.

- Advantages:

- Flexible and easy to install.

- High tear and abrasion resistance.

Advantages of PVC in water and wastewater treatment

Chemical resistance:

- Resistant to most chemicals used in water and wastewater treatment.

Cost efficiency:

- Cheaper than many other materials such as stainless steel or special plastics.

Easy processing:

- Can be easily cut, glued and shaped.

Corrosion resistance:

- Ideal for aggressive media such as acidic or alkaline waste water.

Flame retardancy:

- Self-extinguishing on contact with flames.

Challenges and limits

UV resistance:

- Without stabilizers, susceptible to embrittlement due to UV radiation.

Temperature limitation:

- Not suitable for applications above 60 °C (PVC-U) or 90 °C (PVC-C).

Brittleness in the cold:

- PVC-U can become brittle at temperatures below -15 °C.

Plasticizer in PVC-P:

- Can migrate over time and impair mechanical properties.

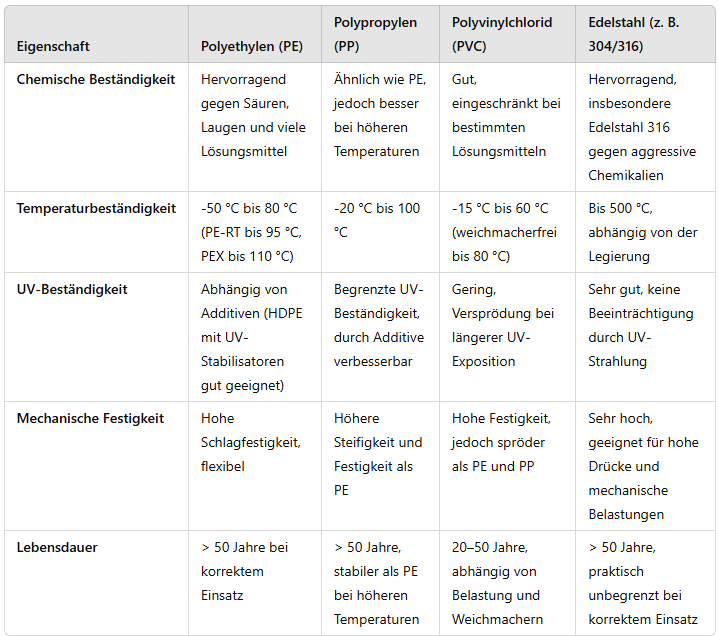

Comparison between PE, PP, PVC and stainless steel

Conclusion

PVC is an extremely versatile and cost-effective material for water and wastewater treatment. It impresses with its chemical resistance, ease of processing and high availability. Despite its limitations in terms of UV and temperature resistance, PVC remains a first-class choice for applications with moderate mechanical and thermal requirements.

For further information on our products, please feel free to contact us at any time!