Precipitation and flocculation are essential processes in industrial wastewater treatment that aim to remove dissolved and colloidal substances in wastewater and convert them into a settleable or filterable form. These processes are particularly important in industries where the wastewater contains high concentrations of heavy metals, organic substances or phosphates. A combination of chemical reactions and physical processes enables efficient removal of pollutants in order to comply with legal requirements.

Table of contents

Technical background

The precipitation and flocculation processes consist of several steps that are specifically adapted to the composition of the wastewater and the substances to be separated:

1. felling

- The aim of precipitation is to convert dissolved ions or colloidal compounds into insoluble solids. Precipitants such as iron(III) chloride, aluminum sulfate or calcium hydroxide are used for this purpose. These chemicals react with the substances dissolved in the wastewater and form hydroxides, phosphates or other poorly soluble compounds, which precipitate as fine particles in the water.

- One specific example is neutralization precipitation, in which the pH value of the wastewater is specifically changed in order to precipitate metals as hydroxides. This is particularly relevant in the electroplating and metal industry, where heavy metals such as nickel, copper or zinc often have to be removed.

- Another variant is sulphidic precipitation, in which sulphides such as sodium sulphide are added. These react with heavy metal ions and form insoluble metal sulphides. This process is extremely effective for removing toxic heavy metals, as metal sulphides are very difficult to dissolve and can be easily separated.

2. flocculation

Flocculation is a crucial step in precipitation and flocculation systems in which special flocculants or polymers are used to aggregate the small particles produced by precipitation into larger flocs. These polymers consist of long molecular chains that bind to the surfaces of the particles and cross-link them together.

There are different types of polymers that differ in their charge (cationic, anionic or neutral).

- Cationic polymers: These carry a positive charge and are particularly suitable for binding negatively charged particles in wastewater.

- Anionic polymers: These have a negative charge and are used to floc positively charged particles.

- Non-ionic polymers: These are neutral and act as bridging agents between particles of different charges.

Mechanism of flocculation

Polymers function through two main mechanisms:

- Charge equalization: Polymers neutralize the surface charges of the particles, which reduces the repulsive forces between the particles. This results in the particles coming closer together and forming larger flakes.

- Bridging: The long chain molecules of the polymers link several particles together to form stable flocs that can be separated by sedimentation or flotation. flotation can be easily separated by sedimentation or flotation.

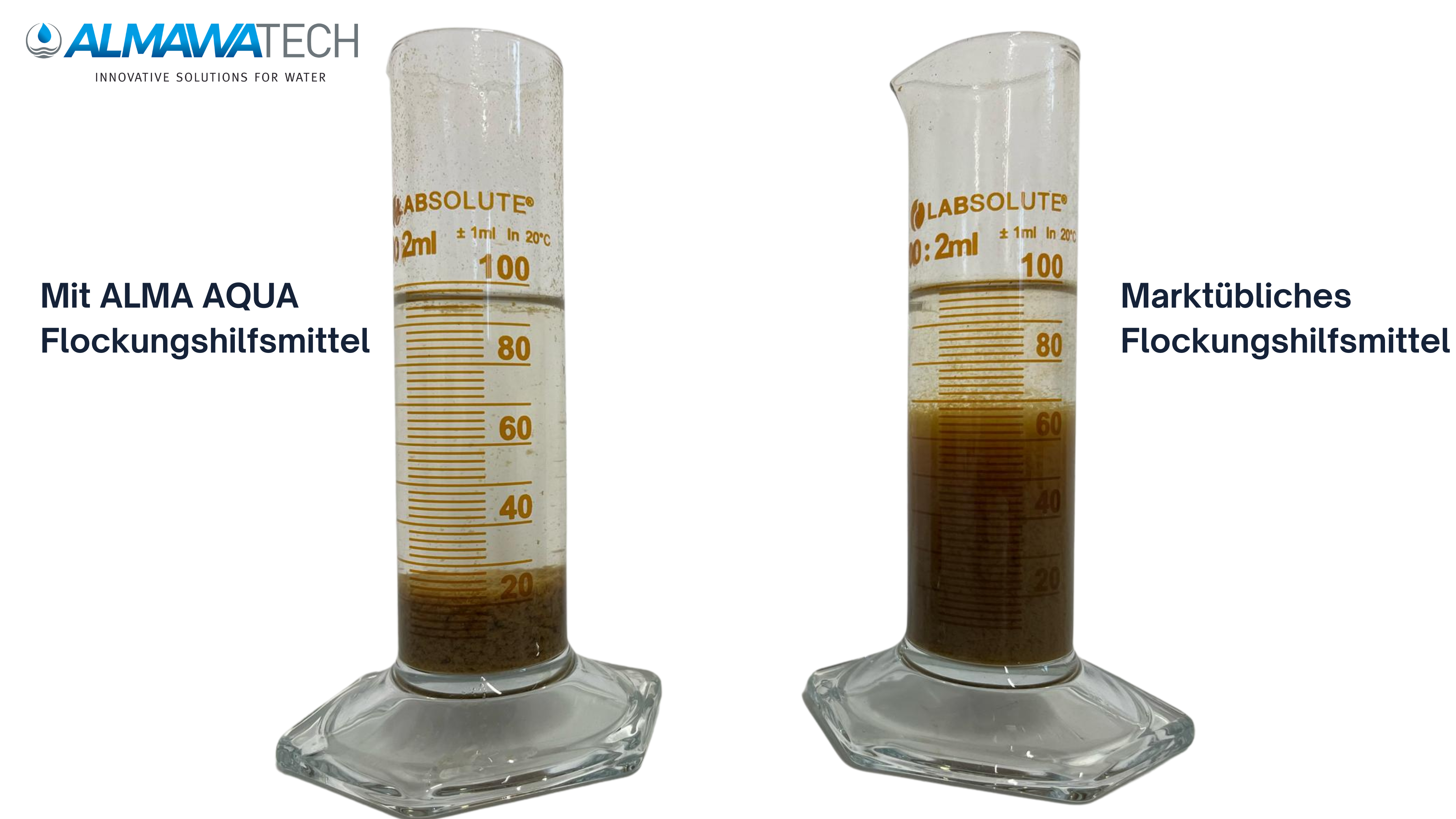

Photo: Comparison of two flocculants, on the left from the ALMA AQUA wastewater product range

Areas of application for precipitation and flocculation processes

Metal processing industry: Precipitation and flocculation processes are used in electroplating and metal processing to remove heavy metals such as zinc, nickel, copper and chromium. This wastewater contains high concentrations of heavy metals, which must be converted into insoluble compounds and removed by a combination of neutralization and sulphide precipitation in order to comply with legal limits.

Food and beverage industry: This produces heavily contaminated wastewater with high phosphate and fat concentrations. Precipitants such as iron or aluminum salts are added to bind and separate these substances. Flocculation is then carried out to form larger flocs that can be easily removed. This prevents the overfertilization of water bodies and improves wastewater quality.

Paper and pulp industry: This industry produces wastewater with high organic loads and fibers. Precipitation and flocculation processes help to bind these substances and settle them as sludge. This reduces the chemical oxygen demand (COD) and supports compliance with wastewater limits.

Textile industry: Wastewater often contains dyes, surfactants and heavy metals, which are treated with precipitation and flocculation processes to bind and separate these pollutants before the water is further treated.

Petrochemical industry: Wastewater is often contaminated with oil residues, hydrocarbons and emulsions. Precipitation and flocculation processes convert these organic compounds into settleable particles, which can then be stabilized and removed by flocculation.

Pharmaceutical industry: The production of medicines leads to wastewater containing a variety of organic and inorganic compounds. Precipitation and flocculation processes are essential here to remove heavy metals, phosphates and other impurities.

Mining and mineral processing: In these areas, high concentrations of heavy metals, sulphates and ultrafine particles occur in wastewater. Precipitation and flocculation processes are used here to effectively remove these substances from the wastewater.

Paint and varnish industry: Wastewater often contains pigments, heavy metals and organic solvents. Precipitation and flocculation are used to bind these substances and remove them from the wastewater. This is particularly important for the removal of dyes and metal ions, which are converted into larger, settleable particles after precipitation by flocculation.

Surface technology: In electroplating and other surface treatment processes, waste water often contains heavy metals, acids and alkalis. Neutralization and precipitation convert heavy metals such as chromium, copper and nickel into insoluble compounds, which are removed by flocculation and subsequent separation.

Precipitation and flocculation process engineering

In precipitation and flocculation plants, the wastewater is first mixed with the appropriate precipitants and flocculants in reaction tanks. Agitators and special pipe loops are used to ensure optimum mixing and reaction time. After the precipitants have been added, the flocculant settles and forms larger particles that are easy to separate. These flocs are separated either by sedimentation, flotation or filtrationdepending on the specific requirements and the wastewater content.

Application of ALMAWATECH products: ALMA CHEM MCW and ALMA NeoDAF

ALMA CHEM MCW is a specially developed CP system (chemical-physical system) from ALMAWATECH, which is suitable for the efficient implementation of precipitation and flocculation. It enables the precise dosing of precipitants and flocculants and can be flexibly adapted to different wastewater compositions. The ALMA CHEM MCW uses the latest load-proportional dosing technology and is designed for easy integration into existing systems to ensure optimum floc formation and particle separation.

Photo: CP system ALMA CHEM MCW for the elimination of heavy metals, AOX, hydrocarbons and cyanides

ALMA NeoDAF is a highly developed flotation plant specially designed for the separation of flocs and suspended solids. This system works according to the principle of dissolved air flotationin which the wastewater is saturated with air under pressure and then expanded. This creates fine air bubbles that attach themselves to the flocs and drive them to the surface, where they are skimmed off as sludge. The ALMA NeoDAF is particularly suitable for maximizing the efficiency of heavy metal and organic compound removal by providing precise control of the process parameters.

Photo: ALMA NeoDAF flotation plant

Conclusion

Precipitation and flocculation are indispensable processes in modern industrial wastewater treatment. Through the targeted use of precipitants and polymers, dissolved and colloidal impurities can be effectively removed, which helps to comply with limit values and improve water quality. Our ALMA CHEM MCW and ALMA NeoDAF offer customized solutions that enable efficient wastewater treatment and can be flexibly adapted to industrial requirements.

For further information on our products, please feel free to contact us at any time!