A neutralization plant is a technical system for regulating the pH value of industrial wastewater in order to bring it to the legally prescribed pH value for discharge into bodies of water or municipal sewage treatment plants. Many industrial processes produce acidic or alkaline wastewater which, if left untreated, could damage the environment as well as pipelines and systems. The task of the neutralization system is to stabilize the pH value of this wastewater through the targeted use of neutralization agents and to bring it to a neutral range (usually pH 6.5 - 9).

Table of contents

How a neutralization system works

In a neutralization plant the pH value of the wastewater is continuously monitored and neutralizing agents such as acids, bases or CO2 are added as required to bring the pH value into the desired range.

pH measurement and control: First, the pH value of the wastewater is measured. Modern systems use pH sensors to continuously monitor the wastewater. These sensors supply the data to the control unit, which then controls the dosing of the neutralizing agents.

Dosing of neutralizing agents:

- Bei sauren Abwässern (pH < 7) wird eine Lauge (z.B. Natronlauge NaOH oder Kalkmilch Ca(OH)₂) zugegeben, um den pH-Wert zu erhöhen.

- For alkaline wastewater (pH > 7), acids (e.g. sulphuric acid H₂SO₄ or hydrochloric acid HCl) are used to lower the pH value.

- A particularly environmentally friendly and sustainable method of pH regulation is the use of carbon dioxide (CO₂), which acts as an acid. CO₂ reacts with water to form carbonic acid (H₂CO₃), which is used to lower the pH. One advantage of this method is that it involves less chemical intervention and the CO₂ is bound through the formation of carbonates, which is less harmful to the environment.

Mixing and reaction time: The wastewater is mixed with the neutralizing agent in special reactors or neutralization tanks so that the chemical reactions can take place completely. The reaction time depends on the composition of the wastewater and the type of neutralizing agent used.

Continuous monitoring: Modern neutralization systems are equipped with automated control circuits that continuously monitor the pH value and immediately add the necessary amount of neutralization agent in the event of deviations.

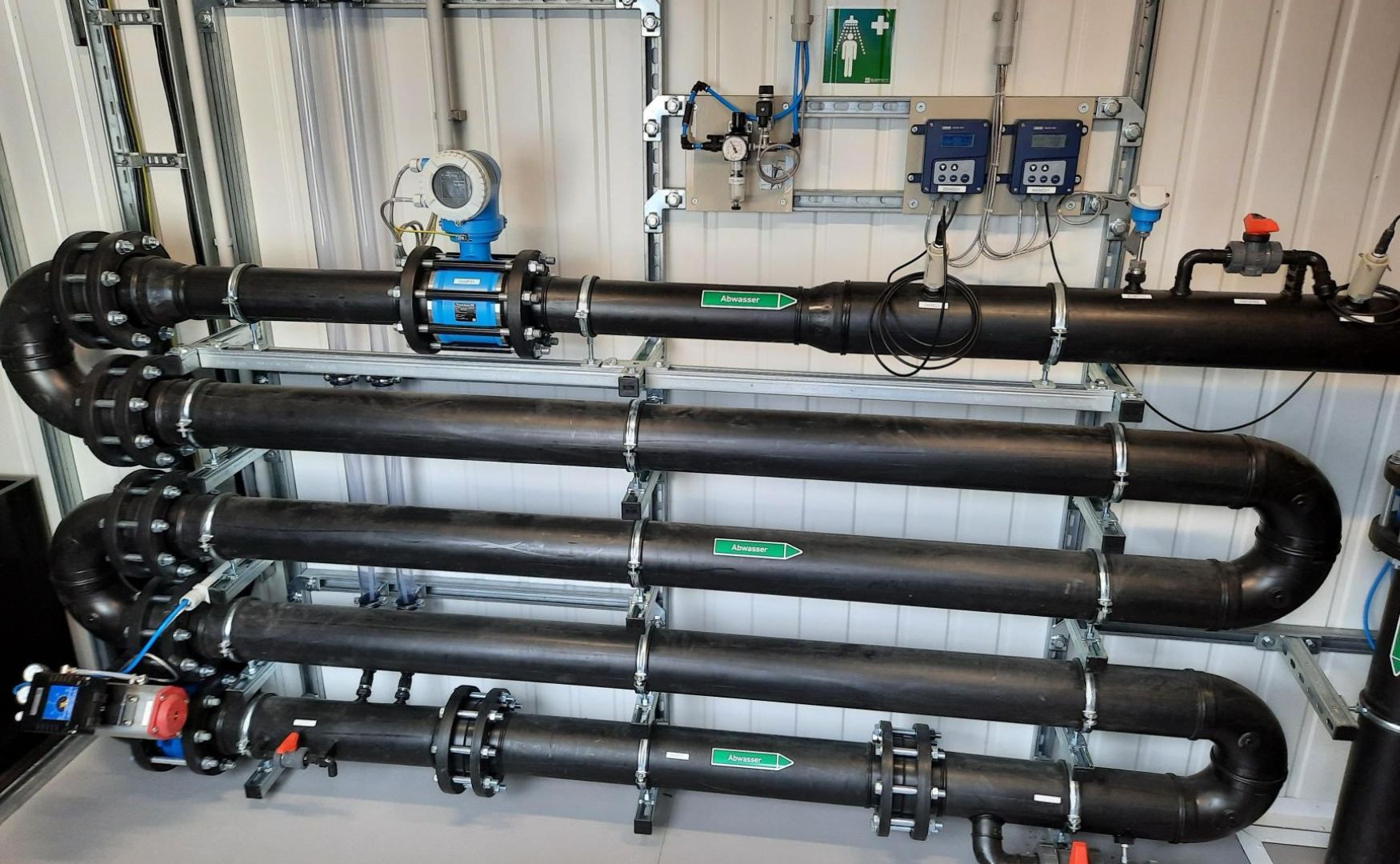

Photo: Reaction section of a pH-controlled neutralization system with automatic dosing of acid and alkali(ALMA Neutra)

Areas of application

Neutralization systems are used in many branches of industry in which acidic or alkaline waste water is produced, including

- Chemical industry: Strongly acidic or alkaline wastewater is often produced here as a result of chemical reactions or process residues.

- Metal processing and electroplating: These areas often produce wastewater with high pH fluctuations that require precise neutralization before they can be treated further or discharged.

- Food and beverage industry: Acidic wastewater is often produced during production, for example during cleaning or through fermentation processes that require neutralization.

- Pharmaceutical industry: The manufacture of medicines and active ingredients can produce highly alkaline or acidic wastewater that must be neutralized.

- Power plants and energy generation: Flue gas desulphurization plants produce acidic wastewater that requires pH regulation.

Our solutions: ALMAWATECH neutralization systems

Neutralization systems from ALMAWATECH offer tailor-made solutions for pH value regulation in industrial processes. Our systems can work flexibly with different neutralization agents such as acids, alkalis or CO₂ and are designed for high loads and fluctuating pH values. The systems are also modularly expandable and equipped with intelligent control systems that ensure precise and efficient dosing of the neutralizing agents.

Photo: Example of a CO2 neutralization system in the ALMA module for a dairy(ALMA Neutra)

Conclusion

Neutralization systems are essential for the safe and environmentally friendly treatment of wastewater. They ensure that the pH value of wastewater is brought within the legally prescribed range in order to prevent damage to the environment and operating equipment. With ALMAWATECH neutralization systems, we offer efficient and tailor-made solutions that enable sustainable and reliable pH regulation.

For further information on our products, please feel free to contact us at any time!

Photo: Example of a neutralization system in ALMA modular design with mixing and equalizing tank(ALMA Neutra)