COD is a technical parameter used in industrial wastewater treatment, particularly in biological processes. It describes the quantity of organic compounds, measured as COD (chemical oxygen demand), which can be degraded per unit volume of a biological reactor in a defined period of time. The COD load is usually given in kg COD/m³-d (kilograms of COD per cubic meter of reactor volume per day).

This parameter is particularly important for the design and dimensioning of biological wastewater treatment plants, as it describes the organic load of a system in relation to its volume. Careful control of the COD volume load is crucial to ensure optimum biological wastewater treatment, as it has a significant influence on the degradation of organic substances by microorganisms.

Table of contents

Technical background

In biological wastewater treatment processes, such as the activated sludge process or anaerobic processes for biogas productionorganic substances in wastewater are broken down by microorganisms. These microorganisms require oxygen to oxidize the organic compounds and convert them into biomass, carbon dioxide and water. The speed of this process depends on various factors, including the amount of organic matter (COD), the concentration of microorganisms (sludge concentration) and the available reactor volume.

The COD load indicates how much organic matter can be degraded per cubic meter of reactor volume per day. It is therefore a measure of the intensity of the biological degradation process. A well-designed biological system achieves a balance between the organic load supplied and the capacity of the system to break down this load.

Significance of the COD room load in practice

The COD space load is a critical design parameter in the design of biological wastewater treatment plants, as it directly influences the efficiency and dimensioning of the plant:

Optimal biological activity:

- Excessive COD loads can lead to an overload of the biological system, as the microorganisms are not able to completely break down the organic substances. This leads to increased COD in the effluent and inefficient wastewater treatment.

- Too low a COD room load, on the other hand, leads to underutilization of the plant, which unnecessarily increases operating costs and leads to inefficient use of biological capacities.

Sludge production:

- The COD space load also influences the amount of excess sludge produced. With a higher space load, more biomass (sludge) is formed, which increases the requirements for sludge treatment.

Oxygen demand:

- As the microorganisms require oxygen to oxidize the organic substances, the COD room load also influences the oxygen requirement of the system. A higher load requires more intensive aeration in order to maintain the biological process.

Application of the COD room load

The calculation of the COD space load is used to dimension the tank volume of a reactor, the sludge return, the aeration systems and other critical components in biological wastewater treatment. Typical areas of application are

1. activated sludge process:

Here, the COD room load is used to dimension aeration tanks and to determine the optimum sludge concentration.

Photo: Classic aeration tank of our ALMA BHU Bio

2. anaerobic wastewater treatment

Anaerobic reactors are often used in food and beverage industries, dairies, paper mills and biogas plants to break down organic substances in wastewater and simultaneously generate energy in the form of biogas. Typical reactors for anaerobic processes are

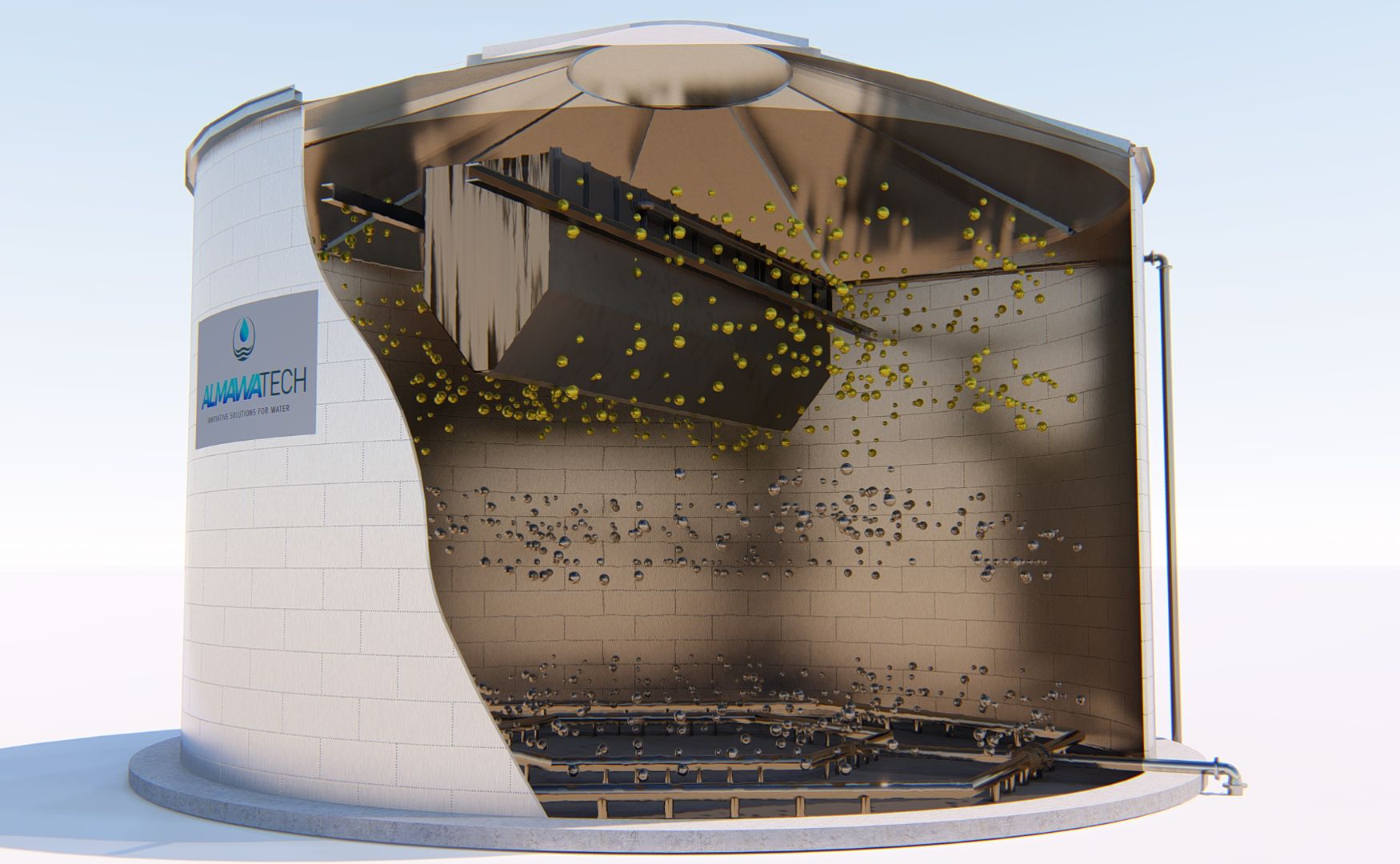

UASB reactors (Upflow Anaerobic Sludge Blanket):

The UASB reactor (Upflow Anaerobic Sludge Blanket) is an anaerobic reactor technology characterized by efficient wastewater treatment and biogas production. The wastewater flows in a counter-current principle from the bottom to the top of the reactor, where it meets a sludge layer consisting of granulated anaerobic microorganisms. These microorganisms break down the organic substances in the wastewater under anaerobic conditions and produce biogas, which consists mainly of methane and carbon dioxide.

Technical specifications:

- Flow direction: From bottom to top (upflow)

- Hydraulic dwell time: Typically between 6 and 12 hours

- Organic loading rate: Up to 10 kg COD/m³-d

- Temperature range: Can be operated in both mesophilic (30-40°C) and thermophilic (50-60°C) areas

- Gas production: 0.25 to 0.35 m³ of biogas per kg of degraded COD

Photo: Schematic representation of our ALMA BIO UASB reactor

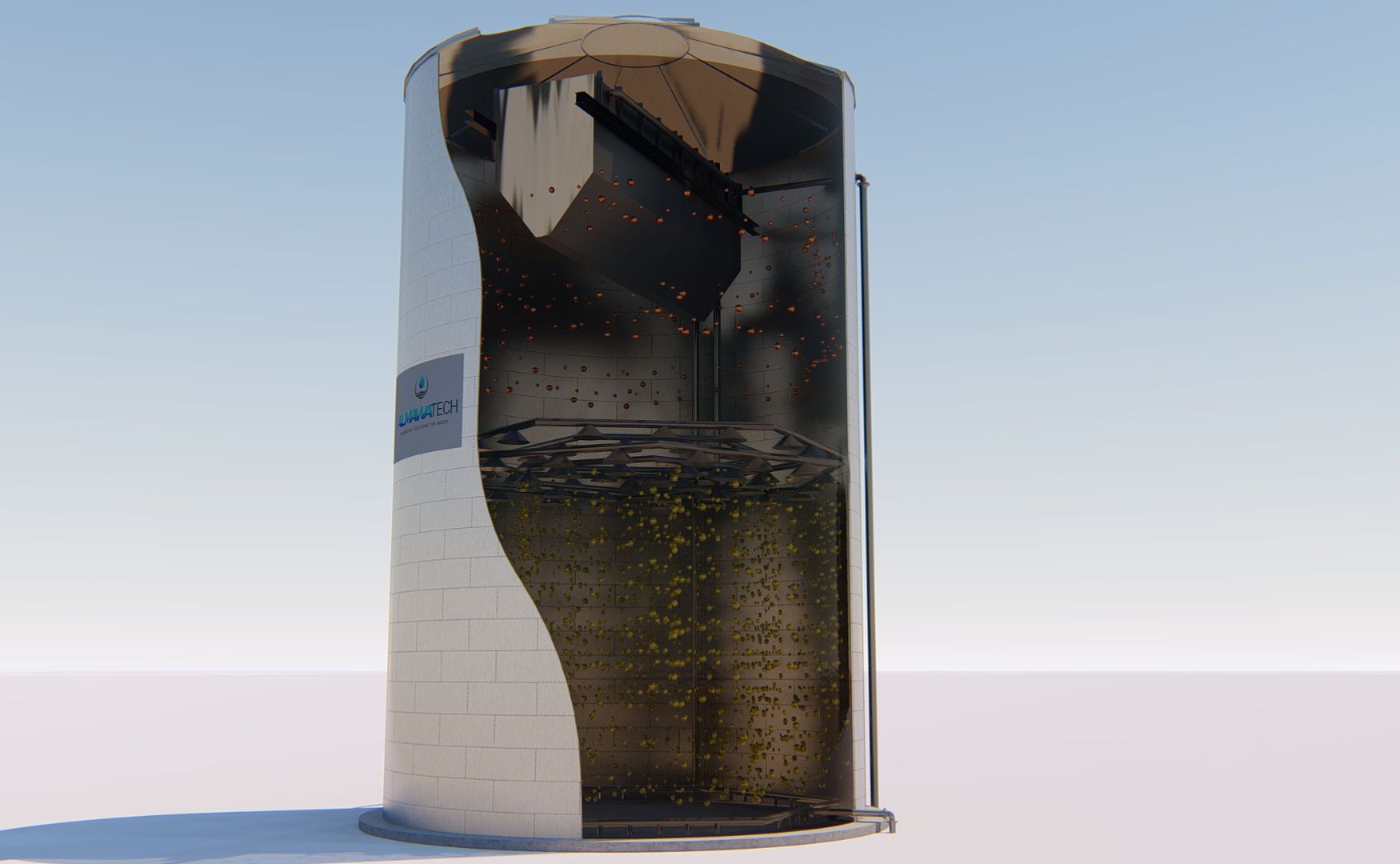

EGSB reactors (Expanded Granular Sludge Bed):

The EGSB reactor (Expanded Granular Sludge Bed) is a further development of the UASB reactor and is characterized by a higher flow rate and better mixing. In the EGSB reactor, the wastewater is fed through the granulated sludge layer at a higher speed, which reduces the hydraulic retention time and increases the organic load. This improved fluid circulation and expansion of the sludge bed makes the reactor more efficient, especially for wastewater with a very high organic load.

Technical specifications:

- Flow direction: From bottom to top, similar to the UASB reactor, but with a higher flow velocity.

- Hydraulic retention time: Typically between 1 and 6 hours, depending on the wastewater composition.

- Organic loading rate: Up to 30 kg COD/m³-d

- Reactor height: EGSB reactors are typically higher than UASB reactors, which leads to better separation of sludge and wastewater.

- Gas production: Similar to the UASB reactor, with a gas production of around 0.3 to 0.35 m³ of biogas per kg of degraded COD.

Photo: Schematic representation of our ALMA BHU BIO EGSB reactor

Gas mixing reactors:

- In our ALMA BHU GMR (gas mixing reactor), the wastewater is treated efficiently under anaerobic conditions, whereby the reactor was specially developed for wastewater with high calcium concentrations. The advanced gas mixing technology of the ALMA BHU GMR ensures optimum mixing of the reaction gases in the wastewater, which greatly improves the biodegradation and precipitation of calcium.The reactor offers a particularly efficient solution for wastewater that is difficult to treat due to its high calcium content. It not only reduces the organic load of the wastewater, but also enables targeted calcium precipitation, which prevents deposits in downstream systems. This ensures stable operation and significantly reduces maintenance costs. The ALMA BHU GMR is therefore ideal for industrial applications where high calcium concentrations in wastewater are a key challenge.

Photo: Photos of our anaerobic gas mixing reactor ALMA BHU GMR

Conclusion

COD is a decisive parameter in biological wastewater treatment, which describes the amount of organic compounds that can be degraded per unit volume of a reactor. It has a significant influence on the efficiency, dimensioning and operating costs of a wastewater treatment plant. With ALMAWATECH 's customized solutions, companies can treat their wastewater efficiently and optimally control the COD load in order to meet legal requirements and operational targets.