An anionic polymer is a water-soluble flocculant that is used in industrial water and wastewater treatment to precipitate and flocculate solid particles and suspended solids. It is a high-molecular polymer that has negative charges (anions) and is able to agglomerate fine particles in the water so that they coalesce into larger flocs. These flocs can then beseparated in CP plants by sedimentation or by flotation plants from the water. Anionic polymers play a central role in processes in which the concentration of suspended solids, organic substances and heavy metals must be reduced in order to improve wastewater quality.

Table of contents

Technical background

Anionic polymers consist of long molecular chains that contain a high number of functional groups that are negatively charged, such as carboxyl groups (-COO-) or sulphate groups (-SO₄²-). These negative charges enable the polymer to interact with positively charged particles (e.g. colloids, metal ions or organic compounds) in aqueous solutions. The electrostatic attraction causes the particles to bind to the polymer and form larger flakes that can be removed more easily.

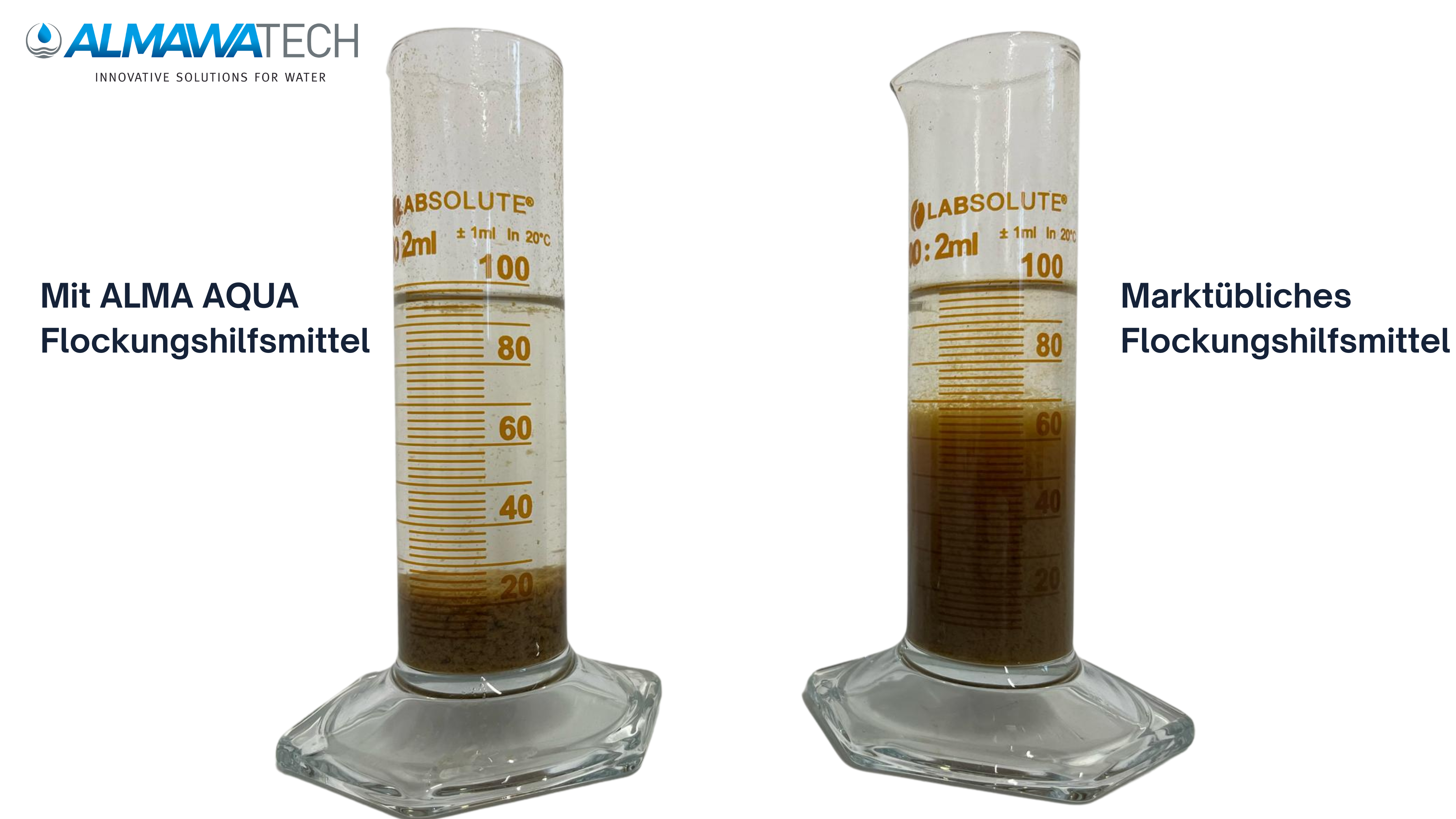

Photo: Comparison between a polymer (flocculant) from ALMAWATECH and a commercially available polymer ( ALMA AQUA Wastewater product overview)

How flocculation works:

Electrostatic interaction: The negative charges of the anionic polymer attract positively charged particles and suspended solids in the wastewater, which are often unstably suspended in the solution.

Floc formation: After the particles bind to the polymer, they crosslink by bridging and coagulate to form larger flakes. These flakes are heavier than the original fine particles and are either sedimented in a sedimented in a CP plant or are separated during flotation to the water surface during flotation.

Separation: The resulting flocs are separated by gravity (sedimentation) or by the action of air bubbles(flotation) and can then be separated and treated as sludge.

Application areas of anionic polymers

Anionic polymers are used in a variety of applications in industrial water and wastewater treatment:

1. wastewater treatment

In industrial wastewater treatment, anionic polymers play a key role in the clarification of wastewater. They are used to remove suspended solids, organic compounds and heavy metals through flocculation. Typical areas of application are the food industry, the chemical industry, paper production and metal processing.

Photo: Pollutants bound in sludge flocs by polymers, also known as flocculants, in our ALMA NeoDAF flotation plant

2. sludge dewatering

In sewage treatment plants, anionic polymers are used for sludge dewatering. They help to compact the sludge and separate the water, which reduces disposal costs and makes sludge treatment more efficient.

3. drinking water treatment

In drinking water treatment, anionic polymers are used to remove organic impurities and particles in order to improve water quality and comply with legal limits.

4. precipitation and flocculation plants

In chemical-physical treatment plants (CP plants) anionic polymers are used to support the formation of flocs and increase the efficiency of precipitation. This is particularly important in the treatment of wastewater with a high content of organic substances or heavy metals.

Photo: Precipitation and flocculation plant, also known as CP plant, ALMA CHEM MCW with sludge dewatering

Our products: ALMA AQUA Wastewater

Under our brand ALMA AQUA Wastewater brand, we offer specially developed anionic polymers and other operating fluids for wastewater applications. These polymers are tailored to various requirements in industrial wastewater treatment and ensure highly efficient flocculation and solids separation. Our polymers are characterized by their high performance, low consumption and ecological compatibility and offer solutions for a wide range of industrial applications, such as in precipitation and flocculation plants, sludge treatment processes and cooling water treatment.

Advantages of anionic polymers

High flocculation efficiency: Anionic polymers have a strong binding affinity to positively charged impurities, which leads to efficient floc formation.

Wide range of applications: They can be used in many different industries, from paper production and food processing to municipal wastewater treatment.

Cost savings: The effective separation of solids can reduce disposal costs as the amount of sludge is reduced.

Reduction of chemical consumption: Through the targeted use of anionic polymers, other chemicals such as precipitants can be used in smaller quantities, which lowers operating costs and reduces the environmental impact.

Challenges and optimization

Dosing: Precise dosing of the anionic polymer is crucial for the process flow. Overdosing can lead to floc instability, while underdosing impairs cleaning performance. Optimized dosing stations are important to ensure the correct use of polymers.

Regeneration and sludge treatment: Flocculation produces sludge that requires further treatment. Here, the use of sludge conditioning agents in combination with anionic polymers can optimize the process.

Conclusion

Anionic polymers are an indispensable aid in industrial water and wastewater treatment and offer an efficient solution for the precipitation and flocculation of suspended solids and impurities. With the right selection and dosage, they can significantly improve the separation processes in various treatment stages while contributing to cost reduction and sustainability. Under the brand ALMA AQUA Wastewater brand, we offer tailor-made solutions and equipment for wastewater treatment to maximize the efficiency and environmental compatibility of your processes.

For further information on our products, please feel free to contact us at any time!