Aluminum chloride is an inorganic compound that is mainly used as a precipitant in industrial water and wastewater treatment. Its main property is its ability to precipitate impurities such as phosphates, heavy metals and organic substances by forming hydroxide complexes in aqueous solutions, thus clarifying the water. Aluminum chloride is available in various forms, including solid powder or solution (often referred to as polyaluminum chloride - PAC), and is widely used in drinking water treatment, wastewater treatment and industrial circuits.

Table of contents

Technical background

In an aqueous solution, aluminium chloride hydrolyzes and forms aluminium hydroxide [Al(OH)₃], which has a high adsorption capacity. These hydroxide flakes bind impurities such as suspended solids, colloidal particles or dissolved ions and remove them from the water by coagulation and flocculation. Aluminum chloride is particularly effective in the removal of phosphate, which is precipitated by the formation of insoluble aluminum phosphate.

You can find an overview of our precipitants, flocculants and other resources for wastewater treatment on the following page: ALMA AQUA Wastewater

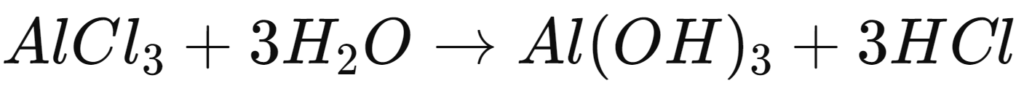

Reaction mechanism of aluminum chloride

Aluminum chloride dissolves in water and reacts as follows:

The resulting aluminum hydroxide agglomerates impurities into larger flocs, which can then be separated by sedimentation, flotation or filtration. The hydrogen chloride (HCl) released in the process lowers the pH value of the water, which is why pH control is often required when using aluminum chloride to ensure efficient settling of the flocs and prevent the pH value from falling too low.

Applications of aluminum chloride

1. drinking water treatment:

In drinking water treatment, aluminum chloride is used as a flocculant to remove turbidity and dissolved organic substances from raw water. It forms large, stable flocs that are removed from the water by sedimentation or filtration. This improves the clarity of the water and reduces turbidity, which is crucial for drinking water quality.

2. wastewater treatment

In industrial wastewater treatment, aluminum chloride is often used for phosphate elimination. Phosphates contribute to the eutrophication of water bodies and must be removed before wastewater is discharged. Aluminum chloride binds the phosphate and precipitates it as insoluble aluminum phosphate. It is also used to remove heavy metals and colloidal particles by precipitation.

3. paper and pulp industry

Aluminum chloride is used in the paper industry as an additive in the production of paper and cardboard. It helps to increase the fiber strength and improve the pulping of the cellulose fibers, which increases the quality of the end product.

4. textile industry

In textile processing, aluminum chloride is used to fix dyes. The binding properties of aluminum ions allow dyes to adhere firmly to the fibers and increase the color fastness of the material.

Advantages of using aluminum chloride

Highly effective at low temperatures:

- Aluminum chloride also works well at low temperatures, making it ideal for applications in cold climates or in cold water streams.

Effective phosphate elimination:

- It is one of the most efficient means of removing phosphate, which is particularly important in wastewater treatment to prevent over-fertilization of water bodies.

Versatile application:

- Aluminum chloride can be used in various areas, from drinking water treatment to industrial processes such as paper and textile production.

Photo: Our automatic dosing station for aluminum chloride(ALMA FLOC M)

Challenges and precautionary measures

pH control: Aluminum chloride leads to the formation of acid (HCl) during hydrolysis, which can lower the pH value of the water. In many cases, a pH adjustment must therefore be made to ensure that the water is brought back into the desired pH range after precipitation. Typically, milk of lime or sodium hydroxide is used for pH control.

Corrosion risks: Since aluminum chloride contributes to the formation of hydrogen chloride, systems and piping that are not corrosion-resistant can be attacked by the use of this precipitant. It is therefore important that the system materials are corrosion-resistant or that appropriate corrosion inhibitors are used.

Sludge production: The use of aluminum chloride leads to the formation of precipitation sludge, which must be removed and disposed of at regular intervals. The amount of sludge produced depends on the dosage and concentration of the substances to be precipitated. Appropriate sludge dewatering (e.g. using our ALMA CFP chamber filter press) and disposal is therefore an important aspect when planning systems that use aluminum chloride.

Photo: Aluminum chlorides, such as polyaluminum chloride (PAC), are particularly suitable for flotation plants, as aluminum-containing precipitants have a lower molecular weight than iron-containing precipitants. The photo shows flotate sludge produced by the addition of PAC. Plant: ALMA NeoDAF flotation plant

ALMAWATECH solutions - Aluminum chloride in practice

Our ALMAWATECH systems use aluminum chloride in various areas of precipitation and flocculation technology. Particularly in phosphate elimination and in our flotation systems(product overview of ALMA NeoDAF flotation systems), our solutions offer an efficient way of removing impurities safely and cost-effectively. Our precipitation and flocculation systems are designed to enable optimum dosing of aluminium chloride while minimizing sludge formation to facilitate operation and disposal.

Conclusion

Aluminum chloride is a highly effective precipitant in industrial water treatment and wastewater treatment, which is used in particular for the removal of phosphates, heavy metals and organic impurities. Its versatility and high efficiency at low temperatures make it a key component in many processes. However, its correct application requires careful pH control and management of sludge production to ensure maximum efficiency while minimizing operating costs.

For further information on our products, please feel free to contact us at any time!