The Advanced Oxidation Process (AOP) describes a group of chemical processes that are based on the generation of reactive radicals, in particular hydroxyl radicals (-OH). These radicals have an extremely high oxidizing power and can efficiently oxidize and break down organic compounds and poorly degradable pollutants in water and wastewater. AOP technology is used in industrial water and wastewater treatment to remove pollutants that are difficult to break down using conventional methods such as filtration, adsorption or biological processes.

Table of contents

Technical background

At the heart of an AOP system is the generation of hydroxyl radicals, which are generated by various combinations of oxidizing agents, catalysts and energy sources. These radicals attack organic molecules and break them down into smaller, often less harmful substances, which can then be more easily biodegraded or filtered. Typical target compounds for AOP processes are pesticides, pharmaceuticals, endocrine disruptors, organic solvents, refractory COD and other micropollutants.

Common AOP procedures include

- UV/H₂O₂ process: The combination of hydrogen peroxide (H₂O₂) and UV light leads to the splitting of the hydrogen peroxide into hydroxyl radicals.

- Ozone-based processes (O₃): Ozone can be used to oxidize pollutants directly or by forming hydroxyl radicals in an aqueous solution.

- Fenton reaction: This process uses a combination of iron(II) salts and hydrogen peroxide to generate hydroxyl radicals in acidic solutions.

Products from ALMAWATECH GmbH

1. ALMA OXI UV

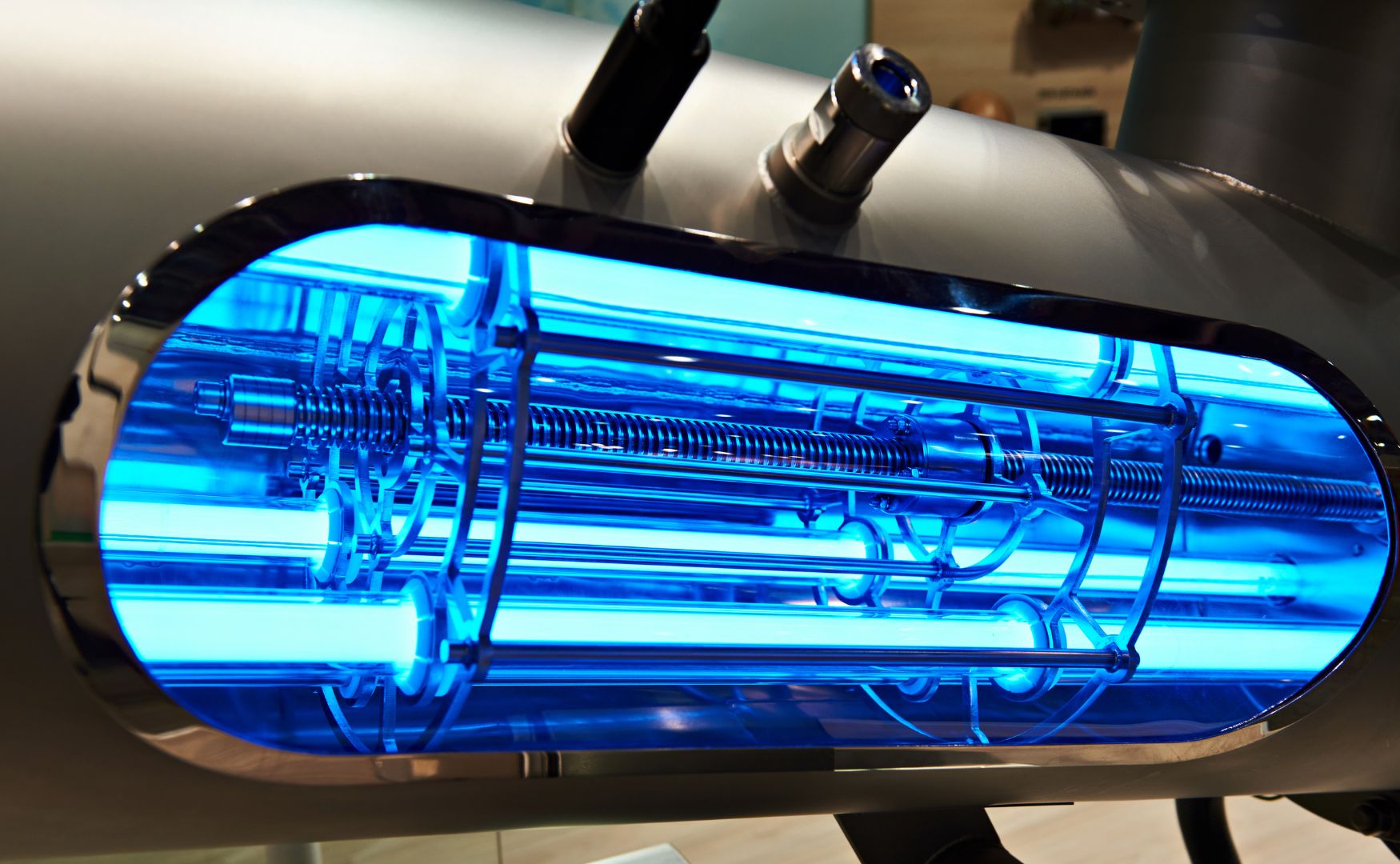

The ALMA OXI UV process is based on the combination of UV light and hydrogen peroxide (H₂O₂). Irradiation with UV light splits the hydrogen peroxide, creating hydroxyl radicals. These radicals react with organic pollutants in the water and oxidize them to more harmless compounds such as water, carbon dioxide and mineral salts. This process is particularly suitable for removing micropollutants, pharmaceuticals and pesticides from wastewater streams. ALMA OXI UV offers high efficiency with low chemical residues and is particularly suitable for industries with high purification requirements, such as the pharmaceutical industry and chemical companies.

Photo: UV reactor with defined UV spectrum for the formation of highly radical hydroxyl radicals of the ALMA OXI UV

2. ALMA OXI Fenton

The ALMA OXI Fenton process uses the classic Fenton reaction, in which hydrogen peroxide (H₂O₂) is used in combination with iron(II) salts to generate hydroxyl radicals. This process is particularly suitable for the treatment of wastewater with high organic loads. It is frequently used in the chemical industry and in the treatment of landfill leachate and sludge to oxidize and break down organic pollutants. The advantage of the Fenton process lies in its high reaction speed and effectiveness, especially with heavily contaminated wastewater.

Photo: ALMA OXI Fenton wastewater treatment plant with sludge dewatering through a chamber filter press

3. ALMA BHU AktivFlock (patented process)

ALMA BHU AktivFlock is a patented process that uses a combination of precipitation, flocculation and oxidation according to the Fenton process at neutral pH. Unlike conventional Fenton processes, which operate at highly acidic conditions, AktivFlock allows application at neutral pH, reducing the complexity of wastewater treatment and increasing process stability. This is particularly beneficial in industries where large amounts of heavy metals, organics and other pollutants need to be efficiently removed without additional pH adjustment of the wastewater.

- Precipitation and flocculation: During precipitation, pollutants in the wastewater are precipitated by adding precipitants such as iron or aluminum salts. Subsequent flocculation causes these particles to form larger flocs that can be easily separated.

- Fenton oxidation at neutral pH: The combination of this process with a Fenton reaction under neutral conditions enables an even more thorough removal of organic compounds, as the Fenton oxidation directly oxidizes and decomposes organic pollutants that are difficult to break down.

ALMA BHU AktivFlock is a highly flexible and efficient system for the treatment of industrial wastewater that offers a cost-effective and environmentally friendly solution. It can be used in various industries, including the textile industry, metal processing and the food industry, where it contributes in particular to the reduction of organic compounds, heavy metals and suspended solids.

Photo: If you would like to know more about the application area of our patented process for removing micropollutants, please read our blog article: Patent AktivFlock

Practical applications of AOP procedures

Advanced Oxidation Processes (AOPs) are used in industrial water and wastewater treatment in areas where conventional processes have reached their limits. These include

- Degradation of micropollutants: The pharmaceutical and cosmetics industries produce wastewater containing hormonally active substances or drug residues that can be efficiently degraded by AOP.

- Treatment of landfill leachate: Heavily contaminated leachate often contains organic compounds and heavy metals, which are removed by a combination of Fenton reaction and flocculation.

- Industrial wastewater with persistent compounds: In the chemical industry or textile production, wastewater with complex compounds is produced that can be effectively and specifically degraded using AOP processes such as ALMA BHU AktivFlock.

Conclusion

The Advanced Oxidation Process (AOP) is a key process in industrial water and wastewater treatment to remove stubborn organic pollutants. With the ALMA OXI UV-, ALMA OXI Fenton- and the patented ALMA BHU AktivFlock process, ALMAWATECH GmbH offers powerful solutions that provide both efficient and sustainable technologies for the oxidation and removal of pollutants in wastewater. These processes are particularly valuable in industries with high demands on wastewater quality and strict legal requirements.

For further information on our products, please feel free to contact us at any time!