ALMA BIOMAGE

All system components and units are conveniently controlled via a touch panel integrated in the control cabinet within the ALMA MODULE. This module also contains the nutrient dosing stations, which feed nutrients to the biogas reactor in a targeted manner in order to achieve an optimum biogas yield.

Your experts for biogas plants - reliably available

References biogas plants

Sugar factory, Germany, ALMA BHU GMR

Construction of an anaerobic treatment stage or biogas plant for the recovery of energy from waste water from a sugar factory with a hydraulic capacity of 220 m³/h in Germany.

Sugar factory, Poland, ALMA BHU GMR

Construction of an anaerobic treatment stage and a biogas plant to generate energy from sugar production wastewater with a hydraulic capacity of 125 m³/h in Poland.

Südzucker AG, Ochsenfurt, ALMA BHU GMR, BIO

Treatment of sugar beet wash water in a biogas plant with pre-acidification and a COD load of 45,000 kg COD/d, for Südzucker in Ochsenfurt.

Biogas plant for Keszthely sewage treatment plant, Hungary, ALMA BHU GMR

Construction of a biogas plant for the sludge utilization of a municipal sewage treatment plant with an energy production of 2,000 kWh/d in Hungary.

Advantages

Downloads

Tender text

Please contact our specialist for biogas plants: E-Mail

Similar products

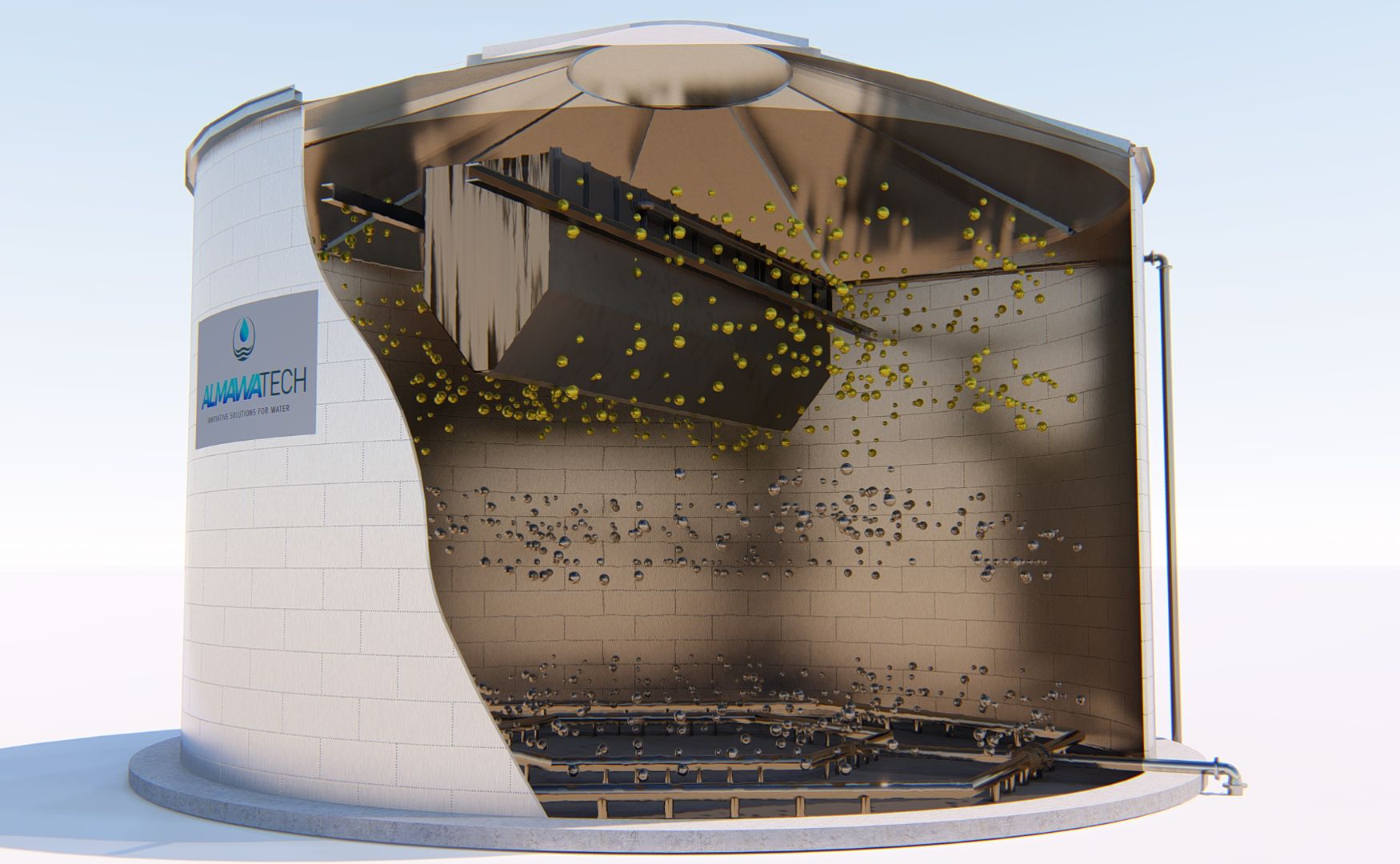

ALMA BIO UASB

Single-stage, anaerobic reactor ALMA UASB for the production of biogas from waste water from the food industry with reactor sizes up to 3,000 m³ and biomass recirculation.

ALMA BHU GMR

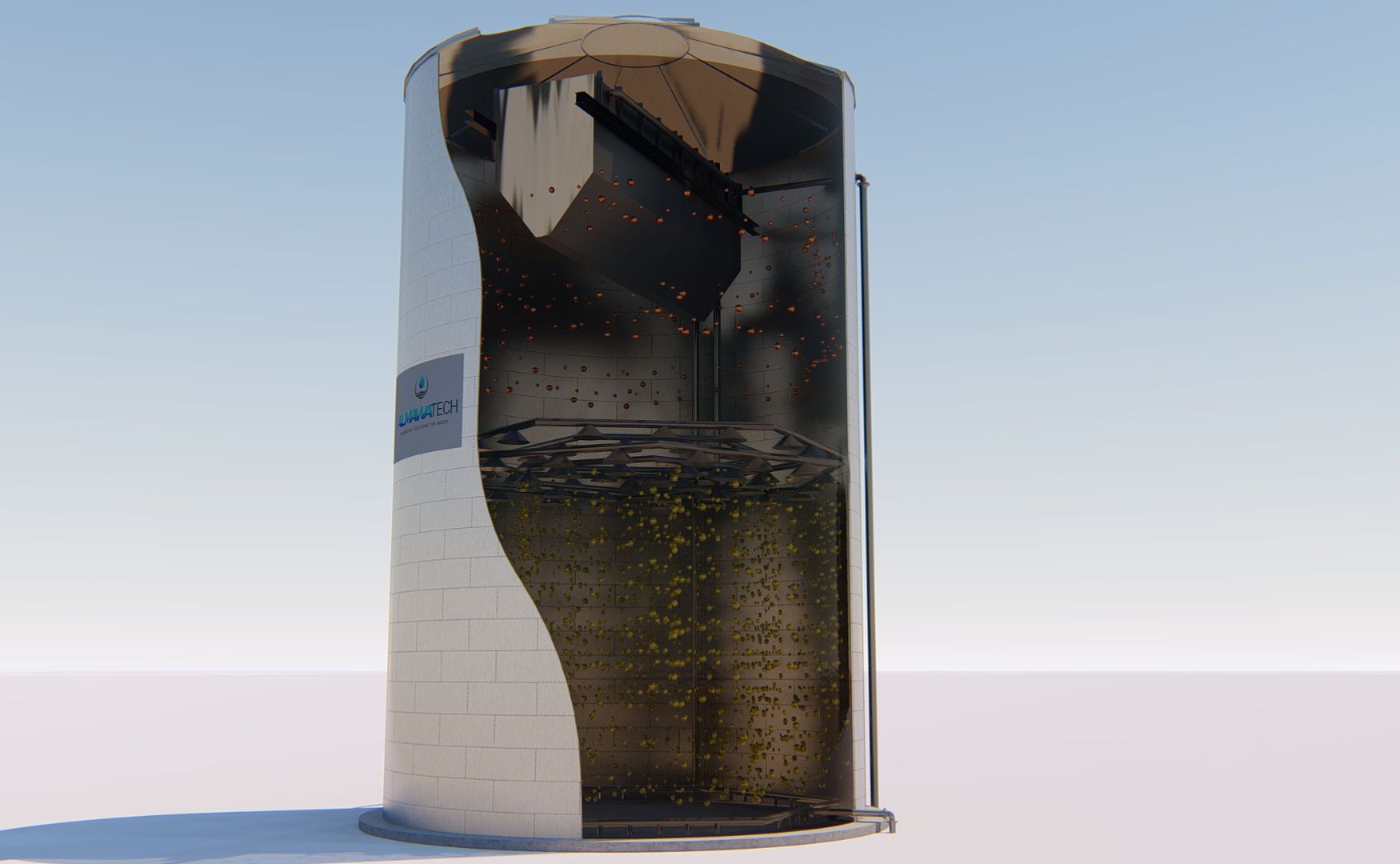

ALMA BHU BIO EGSB

Two-stage, anaerobic reactor ALMA BHU BIO EGSB, which can be fed with a high COD room load due to the two-stage biogas extraction.

Get in touch with us!