A drum screen is a mechanical filter system used in water and wastewater treatment to separate solids from liquid streams. The name is derived from the cylindrical, rotating drum, which is fitted with a screen mesh or perforated plate. The main function of the drum screen is to remove suspended solids, coarse particles or organic residues from the water before it enters downstream processes.

Drum screens are widely used in industrial water and wastewater treatment, as they enable efficient and continuous pre-cleaning with minimal energy and maintenance requirements.

Table of contents

Structure of a trommel screen

A trommel screen consists of the following main components:

Sieve drum

- Construction:

- Cylindrical drum made of stainless steel or corrosion-resistant plastic.

- Covered with a screen fabric or fitted with perforated sheets.

- Screen width:

- Typical range: 0.2 mm to 10 mm, depending on the desired particle size.

- Diameter and length:

- Vary depending on flow capacity and application; typical drum diameters are between 500 mm and 3,000 mm.

Drive system

- Motor and gearbox:

- Ensure the rotating movement of the drum.

- Speed:

- Usually in the range of 1-20 revolutions per minute, depending on the flow rate and strainer capacity.

Water supply

- Inlet area:

- Water enters the drum via a distributor.

- Even water distribution ensures optimum screening performance.

- Drainage area:

- Purified water is discharged from the drum while the solids are retained.

Cleaning mechanisms

- Spray nozzles:

- High-pressure nozzles remove adhering particles from the screen mesh to ensure continuous operation.

- Rotational movement:

- Supports cleaning by gravity and centrifugal force.

Collection and discharge system for solids

- Screw conveyor or chute:

- Transports the retained solids out of the system.

- Collection container:

- Used to store the separated solids before disposal or further processing.

How a drum screen works

The trommel screen works according to a simple but extremely effective principle:

Inlet of the raw water:

- The water to be treated is fed into the rotating drum.

- Even water distribution ensures maximum utilization of the screen surface.

Separation of solids:

- The suspended solids and particles remain on the outer or inner screen surface, depending on the design of the drum screen.

- The purified water passes through the strainer and enters the drain.

Self-cleaning:

- During rotation, the solids are detached from the drum surface by gravity and centrifugal force.

- Spray nozzles remove stubborn deposits and clean the screen mesh.

Solids discharge:

- The separated particles are conveyed by the drum movement to a collecting container or a discharge device.

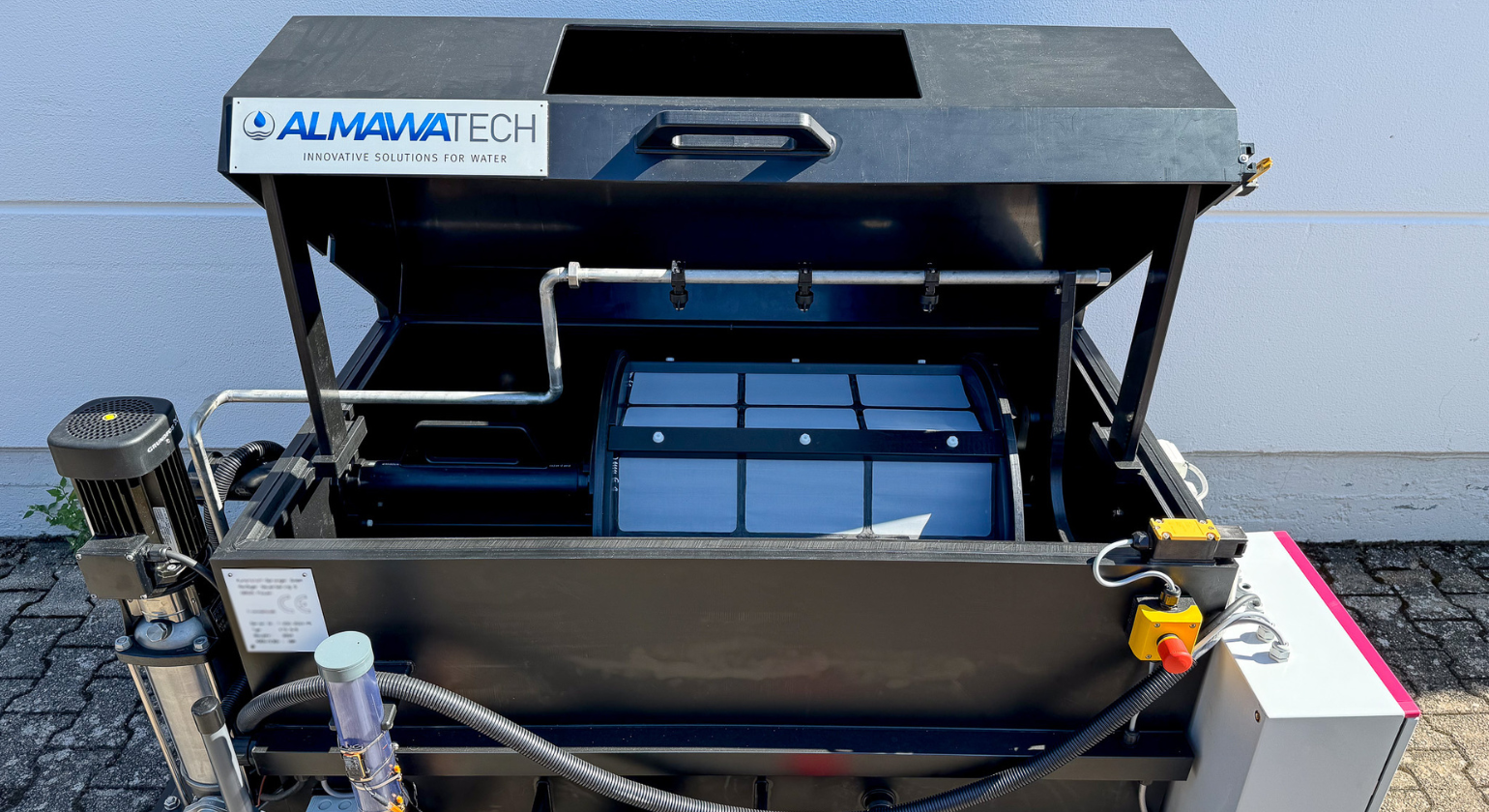

Photo: Drum screen made of PE to prevent corrosion in the treatment of salty wastewater or seawater

Extended areas of application for drum screens in industrial water and wastewater technology

Drum screens are versatile systems that are used in a variety of industrial water and wastewater applications to efficiently remove solids. They are used to optimize downstream treatment stages and help to ensure stable operating conditions.

1. industrial wastewater treatment

In industrial wastewater treatment, drum screens make a decisive contribution to the removal of coarse impurities such as fibers, suspended solids and organic residues. They serve as the first mechanical cleaning unit to reduce the load on subsequent biological or chemical-physical treatment stages.

Purpose

- Solids removal: Reduction of suspended solids and coarse particles to prevent blockages or deposits in downstream systems.

- Process protection: Prevention of operational disruptions that could be caused by coarse materials.

Industries

- Food industry:

- Removal of organic residues such as pulp, peel or seeds from production wastewater.

- Used in breweries, dairies and meat processing plants.

- Pulp and paper industry:

- Retention of paper fibers, wood particles and fillers from process wastewater.

- Enables the return of fibers to the production process or more efficient wastewater treatment.

- Textile industry:

- Separation of textile fibers, lint and color pigments from wastewater produced during dyeing, washing or finishing.

- Chemical industry:

- Removal of solid residues from wastewater that arise during the manufacture of chemical products.

- Metalworking industry:

- Screening of particles, chips or suspended matter from process and rinsing water.

2. drinking water and surface water treatment

Drum screens are widely used in drinking water treatment and in the treatment of surface water. They offer an efficient solution for removing organic substances, sediments and other solids during pre-treatment.

Purpose

- Removal of sediment and algae:

- Pre-treatment of raw water from rivers, lakes or reservoirs that is contaminated with suspended solids, organic particles or algae.

- Optimization of filtration:

- Reduction of the particle load in order to increase the efficiency of downstream filtration stages (e.g. sand filter, activated carbon filter or membrane filtration).

- Protection of treatment plants:

- Prevention of blockages or abrasion on pumps and pipes.

Applications in surface water treatment

- Flood and rainwater treatment:

- Used in the treatment of contaminated water discharged from sealed surfaces or industrial plants.

- Separation of organic residues, leaves and coarse suspended solids.

- Water protection:

- Removal of suspended solids and coarse particles before water from industrial areas is discharged into bodies of water.

3. process water treatment

In industrial process water treatment, drum strainers are an essential element in the efficient recirculation of water. They help to remove suspended solids that could have a negative impact on the operation of cooling or washing water systems.

Purpose

- Solids removal: Removal of particles that could cause corrosion, fouling or deposits in cooling systems and process lines.

- Extension of water quality: Reduction of suspended solids to increase the service life of process water and minimize the consumption of chemicals.

Industries

- Automotive industry:

- Used in car washes to remove paint particles and dirt from rinsing water.

- Electronics industry:

- Removal of dust and particles from process water to meet high purity requirements.

- Cooling water systems:

- Separation of suspended solids and organic residues from open or closed cooling circuits.

Advantages of trommel screens

Efficient solids removal:

- High separation efficiency even with fine particles.

- Consistent cleaning quality thanks to continuous self-cleaning.

Low maintenance:

- Robust construction and few moving parts minimize maintenance requirements.

Compact design:

- Space-saving integration into existing systems.

Flexibility:

- Adaptable to different flow rates and solids loads.

Cost efficiency:

- Low energy consumption and high operational reliability reduce operating costs.

Photo: Drum screen with automatic flushing device

Challenges and solutions

Clogging of the screen mesh:

- If the solids load is high, deposits can block the strainer.

- Solution: Use of powerful spray nozzles and regular inspection.

Corrosion:

- Aggressive media can attack the drum materials.

- Solution: Use corrosion-resistant materials such as stainless steel or GRP.

Solids discharge:

- Insufficient discharge can impair efficiency.

- Solution: Optimization of the discharge device (e.g. screw conveyor).

Conclusion

The drum screen is a versatile and efficient instrument for separating solids in industrial water and wastewater technology. Thanks to its robust design, easy maintenance and high adaptability to different applications, it makes a significant contribution to improving the process stability and efficiency of downstream treatment stages. Whether in the pre-treatment of wastewater, the removal of solids in drinking water systems or process water treatment - the drum screen is a proven technology for modern water treatment requirements.

For further information on our products, please feel free to contact us at any time!