Polypropylene (PP) is a thermoplastic produced by the polymerization of propylene (C₃H₆). Due to its excellent chemical resistance, mechanical properties and temperature stability, PP is a preferred material for numerous applications in industrial water and wastewater treatment. It is used in particular where high demands are placed on corrosion resistance, pressure resistance and long-term stability.

Table of contents

Chemical and physical properties of polypropylene

Polypropylene is a polyolefin and is characterized by its semi-crystalline structure, which determines its mechanical and thermal properties. A distinction is made between different types of PP depending on production and use.

1. molecular structure and variants

Homopolymer (PP-H):

- Consists exclusively of propylene monomers.

- High rigidity and chemical resistance.

- For use in pipelines, tanks and chemical plants.

Block copolymer (PP-B):

- Contains ethylene and propylene blocks that improve impact strength.

- Used in applications with high mechanical loads, e.g. fittings or flotation systems.

Random copolymer (PP-R):

- Uniform distribution of ethylene in the propylene chain.

- Improved transparency and flexibility, suitable for hot water pipes and special membrane carriers.

2. mechanical and chemical properties

Chemical resistance:

- Excellent against acids, alkalis, solvents and many organic chemicals.

- Limited resistance to strongly oxidizing substances (e.g. concentrated sulphuric acid, halogens).

Temperature resistance:

- Application range: -20 °C to 100 °C.

- Higher resistance to temperatures than polyethylene (PE), especially under continuous thermal stress.

Mechanical properties:

- Higher rigidity and strength compared to PE.

- Good impact strength, especially with block copolymers (PP-B).

Density:

- Low (approx. 0.91 g/cm³), lighter than many other plastics.

UV resistance:

- Limited natural UV resistance, but can be optimized with additives such as carbon black or UV stabilizers.

Photo: Our ALMA NeoDAF HD flotation system for small wastewater streams with flotation tank made of PP

Polypropylene production process

Polypropylene is produced using Ziegler-Natta catalysts or metallocene catalysts in a polymerization process. The properties of the end product are defined by the choice of catalyst, reaction conditions and post-treatment.

Gas phase polymerization:

- Ethylene and propylene are polymerized in the gas phase.

- Advantages: High purity and control of material properties.

Suspension polymerization:

- Polymerization in a solvent or liquid.

- Used for specialty polymers such as random copolymers.

Additives:

- UV stabilizers, antioxidants and dyes are added to optimize the material properties.

Applications of polypropylene in water and wastewater treatment

Polypropylene is used in various components and systems in water and wastewater technology, especially where resistance to aggressive media and flexibility are required.

1. piping systems

- Application:

- Transportation of drinking water, waste water, chemicals and process fluids.

- Suitable for hot and cold water systems.

- Advantages:

- Low weight, easy installation thanks to welding process (e.g. hot air welding).

- High pressure and temperature stability, especially with PP-R pipes.

- Technology:

- Welded joints such as butt welding or electrofusion ensure reliable and tight connections.

2. containers and tanks

- Application:

- Storage of acids, alkalis and process chemicals in wastewater treatment.

- Used in sewage treatment plants for sludge and chemical tanks.

- Advantages:

- High corrosion resistance and long service life.

- Easy to shape and assemble.

3. flotation plants

- Application:

- Manufacture of floats, separation tanks and components in dissolved air flotation plants (DAF).

- Advantages:

- Chemical stability ensures a long service life in contact with oily waste water and chemicals.

4. pumps and fittings

- Application:

- Production of chemical pumps, valves and fittings.

- Use in corrosive environments.

- Advantages:

- Resistant to chemical attack and wear.

- Lightweight yet pressure-resistant.

Photo: Our CP system ALMA CHEM MCW with reactors made of PP

Advantages of polypropylene in water and wastewater treatment

Excellent chemical resistance:

- Resistant to most chemicals used in water and wastewater treatment, such as acids, alkalis and organic solvents.

Easy processing:

- Weldability and formability enable simple installation and cost-effective production.

High temperature and pressure resistance:

- Particularly suitable for hot water systems and applications with moderate pressure.

Cost efficiency:

- Cheaper than many metals and special plastics, yet durable and low-maintenance.

Sustainability:

- Polypropylene is fully recyclable, making it an environmentally friendly choice.

Challenges and limits

UV resistance:

- Without additives, PP can become brittle under UV radiation. Solution: Use UV stabilizers or protective coatings.

Temperature limitation:

- Use at temperatures above 100 °C is not recommended. Alternatives such as stainless steel or PEEK are required for higher temperatures.

Oxidizing chemicals:

- Limited resistance to strongly oxidizing substances, which limits the possible applications.

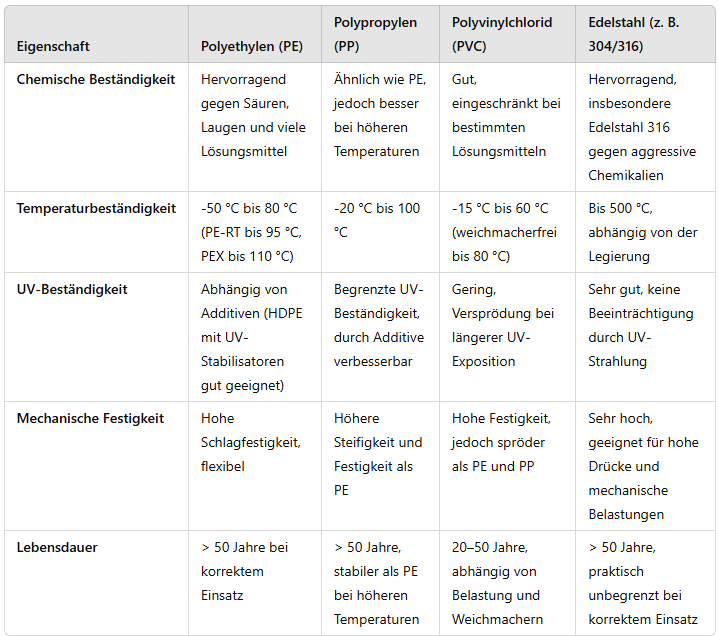

Comparison between PE, PP, PVC and stainless steel

Conclusion

Polypropylene (PP) is an extremely versatile material that is ideally suited to the requirements of water and wastewater treatment. Its chemical resistance, temperature resistance and ease of processing make it a cost-effective choice for piping, tanks, flotation systems and membrane technologies. Despite limited UV resistance and temperature limits, PP offers long-term solutions for industrial applications through targeted modifications and additives.

For further information on our products, please feel free to contact us at any time!