Polymer is a collective term for chemical compounds that consist of long chains of repeating molecular units, so-called monomers. Due to their specific structure and chemical properties, polymers are extremely versatile, especially in industrial water and wastewater treatment. They play a crucial role as flocculants, binders and in various applications to improve the separation of solids and liquids to ensure compliance with environmental standards and increase the efficiency of purification processes.

Table of contents

Technical background

Polymers consist of repeating structural units that are linked together by covalent bonds. The chemical structure and molecular weight of a polymer influence its physical and chemical properties, such as solubility, viscosity and reactivity. These properties are crucial for use in water and wastewater treatment:

Cationic, anionic and non-ionic polymers:

- Cationic polymers carry positive charges and are particularly effective in treating wastewater with negatively charged particles and organic impurities. They are often used to flocculate sludge and remove impurities in wastewater from the metal processing and paper industries.

- Anionic polymers are negatively charged and are preferably used in wastewater with positively charged impurities, for example in wastewater from the food and beverage industry.

- Non-ionic polymers have no electrical charge and are particularly suitable for the flocculation of particles in wastewater with a neutral pH value and varying charge states of the impurities.

Molecular weight and charge density:

- High molecular weight polymers produce larger flocs that settle more easily and can be filtered better, which is particularly advantageous in applications with a high solids load.

- The charge density determines the bonding strength on particle surfaces. Polymers with a high charge density are well suited for agglomerating strongly negatively charged particles, whereas polymers with a low charge density are better suited for wastewater with lower or fluctuating charges.

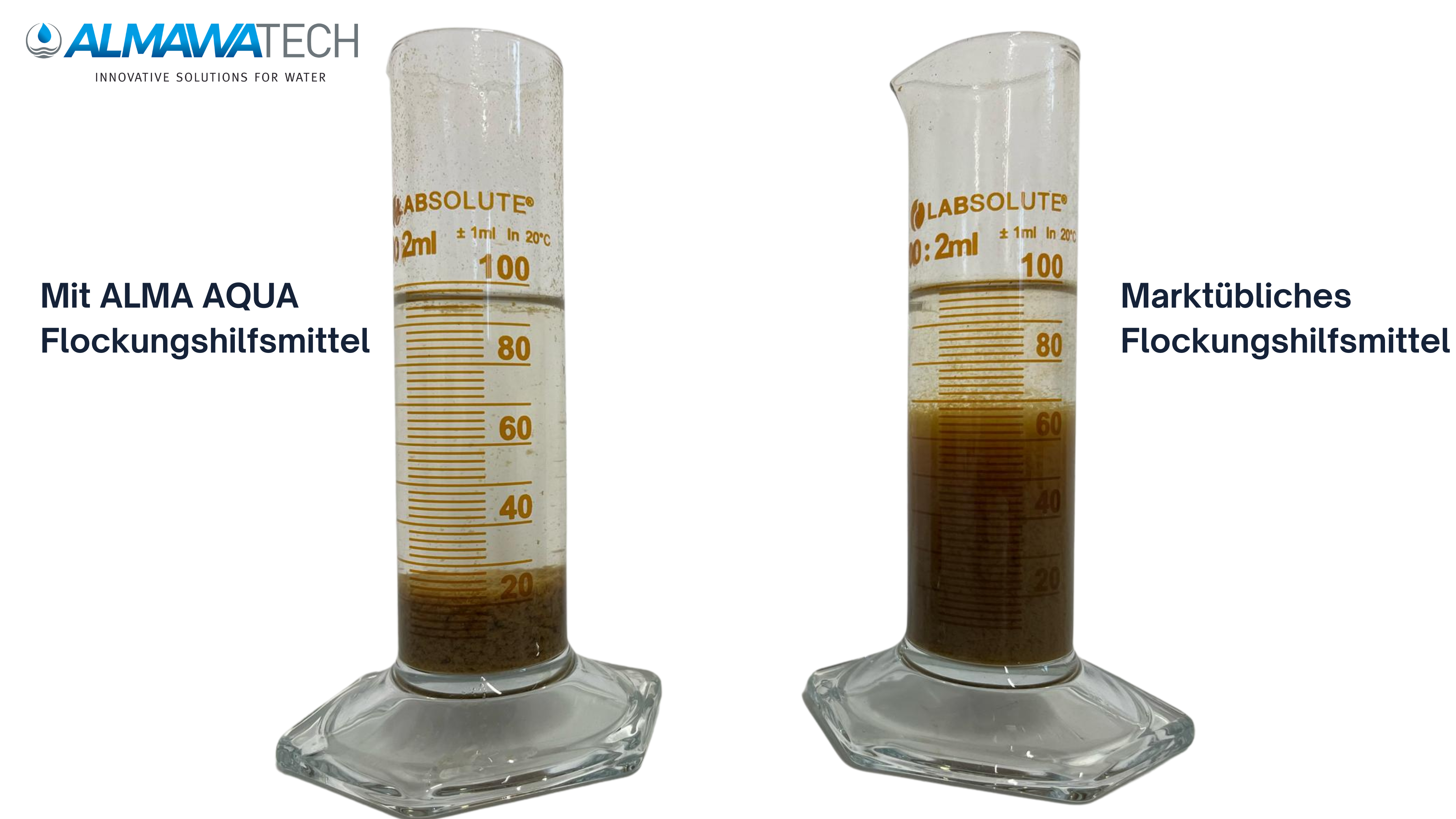

Photo: Comparison between a polymer (flocculant) from ALMAWATECH and a commercially available polymer ( ALMA AQUA Wastewater product overview)

Functionality and application in wastewater treatment

In industrial water and wastewater treatment, polymers are primarily used as flocculants. They promote the formation of large and stable flocs by neutralizing the electrostatic charge of the particles in the water and binding them together into larger units. The use of polymers improves the efficiency of solids separation, as larger flocs are formed by sedimentation in CP plants or by flotation and filtration can be better separated.

Typical applications and functions

Flocculation and coagulation:

- By adding polymers to the wastewater stream, the electrostatic charge of the suspended solids is neutralized, causing them to aggregate into flocs. This is crucial for the efficient separation of solids, especially in wastewater with high concentrations of organic and inorganic particles.

- Polymer flocculation is used in many industries, including paper manufacturing, textiles, metal processing and food processing. Polyacrylamides, a widely used class of polymers, are particularly effective here as they have high floc stability and a strong binding effect.

Sludge conditioning:

- Polymers are used in sludge treatment to improve the water-binding properties of the sludge. They facilitate dewatering and make the sludge easier to handle and dispose of. Cationic polymers are particularly helpful here, as they effectively separate the water by binding to the negatively charged particles in the sludge.

- Sludge conditioning is an important application in wastewater treatment plants, as it reduces disposal costs and improves the efficiency of the entire wastewater treatment process.

Colloidal stabilization and dispersion:

- Anionic and non-ionic polymers are often used to stabilize or disperse colloidal particles in industrial processes to ensure uniform distribution of fine particles and prevent deposits.

- This application is often found in coal processing, ceramics production and other areas where colloidal impurities pose a challenge.

Photo: Precipitation and flocculation plant, also known as CP plant, ALMA CHEM MCW with polymer dosing

Advantages and challenges of using polymers

Advantages:

- High efficiency and low dosage: Polymers are extremely effective at low dosages and enable efficient separation of solids, which reduces chemical consumption and lowers operating costs.

- Versatility: Thanks to the wide range of cationic, anionic and non-ionic polymers available, solutions can be tailored to a wide variety of wastewater compositions and industrial requirements.

- Reduced sludge volumes: Due to the effective floc formation, polymers reduce the sludge volume, which reduces disposal costs and simplifies sludge handling.

Challenges:

- Precise dosing and control: The effectiveness of polymers depends heavily on precise dosing and process control. Overdosing can lead to a deterioration in wastewater quality and increase costs.

- Temperature and pH sensitivity: The efficiency of polymers can be affected by extremely high temperatures or pH values, which can limit their effectiveness in certain applications.

- Residues and environmental compatibility: Some synthetic polymers, such as polyacrylamides, can leave residues in treated wastewater and pose a challenge in terms of environmental compatibility. Biodegradable polymers are being developed as an alternative to increase environmental sustainability.

Photo: Automatic dosing and preparation station for polymer (flocculant) ALMA Floc AC with a treatment capacity of up to 2,000 l/h

ALMAWATECH's polymer solutions: ALMA AQUA Wastewater

As a specialist for water and wastewater treatment, ALMAWATECH offers with ALMA AQUA Wastewater offers a comprehensive selection of polymers that are specially tailored to industrial applications. Our product range includes cationic, anionic and non-ionic polymers that can be adapted to the specific requirements and compositions of your wastewater. Our experienced team will be happy to analyze and test your wastewater in the laboratory to determine the ideal polymer solution and optimal dosage for your requirements. With our tailor-made solutions, we help you to achieve maximum efficiency in wastewater treatment, reduce operating costs and promote sustainable processes.

Conclusion

Polymers are indispensable components in industrial water and wastewater treatment, significantly increasing the efficiency of flocculation and coagulation processes. With a variety of chemical structures and charge properties, they offer customized solutions for a wide range of industrial applications, from sludge conditioning to flocculation of organic and inorganic impurities. ALMAWATECH provides a comprehensive portfolio of polymers and offers the optimum solution to improve your wastewater treatment through application-specific advice and laboratory analyses.

For further information on our products, please feel free to contact us at any time!