Polyacrylamide (PAM) is a versatile polymer used in industrial water and wastewater treatment as a flocculation and coagulation aid. flocculant and coagulation aid. and coagulation aids. It has a high molecular mass and is available in various forms - as a powder, liquid or emulsion. Depending on the application, polyacrylamides can be anionic, cationic or non-ionic and offer an efficient solution for the removal of suspended solids, dewatering of sludge and clarification of wastewater. Polyacrylamide is particularly valuable in wastewater treatment as it supports the formation of stable flocs that can be easily separated.

Table of contents

Technical background and properties of polyacrylamide

Polyacrylamide is a polymer of acrylic acid and consists of long molecular chains with repeating acrylamide groups. The structure of polyacrylamide can be chemically modified as required to add different functional groups, allowing PAM to carry both positively and negatively charged ions. The specific behavior of polyacrylamide in water depends on the charge of the polymer and the type of impurities in the wastewater. The most important property of PAM is its ability to act as a flocculant by binding particles to itself and thereby promoting the formation of large, sedimentable flocs.

Variants of polyacrylamide

Anionic polyacrylamide (APAM):

- Anionic PAM carries negative charges and is used in wastewater containing positively charged impurities. It is well suited for the treatment of suspended solids and organic compounds. APAM is often used in the paper and pulp industry, metal processing and the food industry.

Cationic polyacrylamide (CPAM):

- Cationic PAM carries positive charges and is particularly effective for the flocculation of organic matter and for wastewater containing negatively charged particles or colloidal substances. CPAM is used in sludge conditioning, dewatering in chamber filter presses and municipal wastewater treatment, as it forms a strong bond with biological material and improves dewatering properties.

Non-ionic polyacrylamide (NPAM):

- Non-ionic PAM has no electrical charge and can be used in wastewater with fluctuating pH values and changing charge ratios of the particles. NPAM is used as a supplement to ionic polymers and is particularly useful when the charge of the particles in the wastewater varies.

Copolymer polyacrylamide:

- The combination of anionic and cationic groups in a polyacrylamide molecule creates a copolymer that can be flexibly applied to different types of wastewater and is used as a universal flocculant in heavily contaminated wastewater.

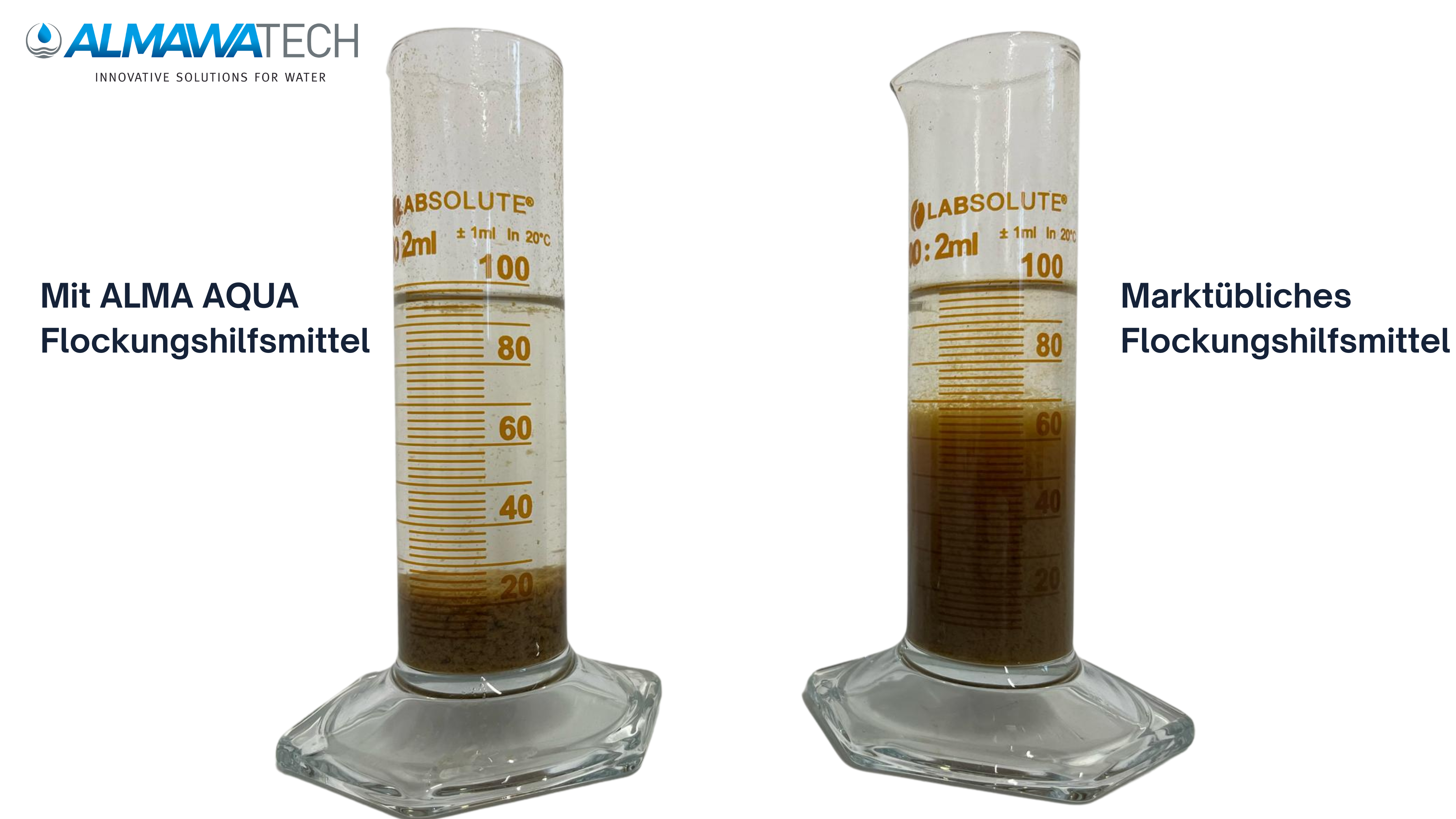

Photo: Comparison between a polymer (flocculant) from ALMAWATECH and a commercially available polymer ( ALMA AQUA Wastewater product overview)

Functionality of polyacrylamide in water and wastewater treatment

The main task of polyacrylamide is to act as a flocculant, which supports coagulation and forms stable, large flocs. This process is particularly essential in wastewater treatment, as very fine particles and colloidal impurities often cannot be removed by simple filtration, flotation or sedimentation in CP plants. The polymer chains of polyacrylamide act by two mechanisms:

Bridging:

- The long molecular chains of the polyacrylamide can be deposited around several particles and form a bridge between them. This leads to the formation of large flocs that can be more easily separated by sedimentation in CP systems, flotation or filtration. Bridging is particularly effective in removing fine particles as they create a stable structure that settles easily under the influence of gravity or by mechanical means such as flotation.

Charge neutralization:

- The ionic charge of the polyacrylamide neutralizes the surface charges of the particles in the wastewater so that they no longer repel each other and form flocs. This neutralization is important for the treatment of colloidal particles, which would remain in a stable suspension due to their surface charge.

Applications of polyacrylamide in practice

Polyacrylamide is an extremely versatile flocculant and is used in various industries, especially in wastewater treatment, in the dewatering of sewage sludge and in drinking water treatment.

Paper and pulp industry:

- In paper production, polyacrylamide is used to remove solids and fibers from wastewater. Anionic polyacrylamide is often used for sedimentation and solids separation and improves the clarity of the process water.

Metal processing and electroplating:

- In metalworking, polyacrylamide is used to remove heavy metals and to separate metal sludge. Here, mainly anionic polyacrylamide is used to optimize the separation of suspended solids and metals.

Food and beverage industry:

- Wastewater from food processing contains high levels of organic substances and suspended solids. Cationic polyacrylamide is used here to flocculate fats, oils and other organic compounds and improve wastewater quality.

Drinking water treatment:

- Polyacrylamide is used in drinking water treatment to remove turbidity and improve filtration. Especially in areas with cloudy or sandy water, polyacrylamide is used to improve water quality and enable clearer treatment.

Sludge conditioning and dewatering:

- Polyacrylamide is used in the dewatering of sewage sludge in municipal and industrial wastewater treatment plants. The addition of cationic polyacrylamide improves dewatering efficiency and reduces the water content of the sludge, which lowers transportation and disposal costs.

Photo: Precipitation and flocculation plant, also known as CP plant, ALMA CHEM MCW with polymer dosing

Advantages and challenges of using polyacrylamide

Advantages:

- High flocculation efficiency: Polyacrylamide enables fast and effective flocculation and improves the separation of solids and suspended matter.

- Versatility: By adapting to different charge types (anionic, cationic, non-ionic), PAM is suitable for a wide range of wastewaters.

- Reduction in operating costs: Efficient flocculation leads to better solids separation, which reduces post-treatment processes and lowers operating costs.

Challenges:

- Sensitivity to pH and temperature: The effectiveness of polyacrylamide can be affected by pH and temperature, which requires precise control.

- Dosage: Overdosing can lead to the formation of excessively large flakes that are difficult to settle. On the other hand, underdosing can lead to insufficient flake formation.

Polyacrylamide at ALMAWATECH: ALMA AQUA Wastewater

ALMAWATECH offers a wide range of polyacrylamide products under the brand name ALMA AQUA Wastewater which are adapted to specific water and wastewater treatment requirements. Our polyacrylamides are available in anionic, cationic and non-ionic form and are specially adapted to the individual requirements of our customers. Through laboratory analyses and tests, we support our customers in selecting the optimum flocculant and offer customized solutions for different applications.

Photo: Automatic dosing and preparation station for polymer (flocculant) ALMA Floc AC with a treatment capacity of up to 2,000 l/h

Conclusion

Polyacrylamide is an indispensable flocculant in industrial water and wastewater treatment. Thanks to its high flexibility and adaptability to different types of wastewater, PAM enables efficient floc formation, resulting in improved water quality and lower disposal costs. With the support of ALMAWATECH and our ALMA AQUA Wastewater product line, companies can choose the right polyacrylamide to achieve maximum efficiency in water and wastewater treatment.

For further information on our products, please feel free to contact us at any time!