Mineralization is a fundamental biological and chemical process in which organic substances are converted by microorganisms or chemical reactions into inorganic compounds such as carbon dioxide (CO₂), water (H₂O) and inorganic nutrients (e.g. ammonium, nitrate or phosphate). Mineralization plays a key role in industrial water and wastewater technology, as it contributes to the complete removal of organic impurities and the stabilization of pollutants. This process is essential for the operation of biological wastewater treatment plants and chemical treatment systems.

In this article, the mechanisms, technical background and applications of mineralization are explained in detail, with a focus on the practical challenges and solutions in industrial water technology.

Table of contents

What is mineralization?

Mineralization refers to the conversion of organic substances into inorganic end products through microbial or chemical degradation. It includes processes such as hydrolysis, oxidation and the release of minerals. The process is crucial for the long-term stability and reusability of water and contributes to the elimination of environmentally hazardous substances.

Examples of mineralized end products:

- Carbon: CO₂ (carbon dioxide) or CH₄ (methane in anaerobic processes).

- Nitrogen: NH₄⁺ (ammonium), NO₃- (nitrate), N₂ (gaseous nitrogen).

- Phosphorus: PO₄³- (phosphate).

Mechanisms of mineralization

Mineralization involves several biological and chemical steps that vary depending on the environmental conditions:

1. biological mineralization

Microorganisms such as bacteria, fungi and archaea play a central role in biological mineralization. The process is determined by the availability of oxygen (aerobic or anaerobic) and electron acceptors.

Aerobic mineralization:

- Oxygen (O₂) serves as an electron acceptor.

- Organic substances are completely oxidized to CO₂ and H₂O.

- Example: Degradation of glucose to CO₂ and H₂O in a biological wastewater treatment plant.

Photo: Aeration tank with denitrification and nitrification for wastewater from the food industry (process: ALMA BHU BIO)

Anaerobic mineralization:

- Alternative electron acceptors such as nitrate (NO₃-), sulphate (SO₄²-) or carbon dioxide (CO₂) are used.

- End products can be CH₄, H₂S or N₂.

- Application: Biogas production in digestion towers.

Photo: anaerobic treatment in the ALMA BHU GMR biogas reactor

Anoxic conditions:

- Nitrogen compounds such as nitrate or nitrite (NO₂-) are used as electron acceptors.

- The end product is gaseous nitrogen (N₂).

- Example: Denitrification in sewage treatment plants.

Photo: Our ALMA BioFil Compact biofiltration system with nitrification and denitrification for in-house water recycling

Challenges of mineralization

1. incomplete degradation:

In some cases, organic substances are only partially degraded, which can lead to toxic intermediate products.

- Solution: Use of advanced oxidation processes (AOPs) such as ozonation or UV photolysis.

2. high energy requirements:

Aerobic processes require intensive ventilation, which results in high operating costs.

- Solution: Combination with anaerobic processes to recover energy from biogas.

3. sensitivity of biological processes:

Biological systems react sensitively to fluctuations in pH value, temperature or nutrient concentration.

- Solution: Precise process monitoring and control.

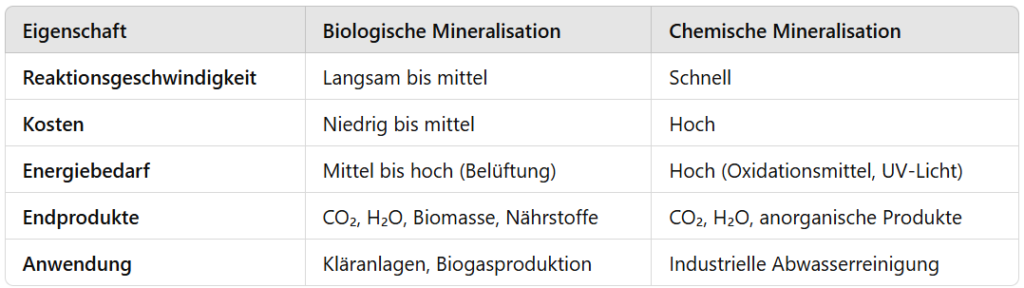

Comparison of biological and chemical mineralization

Conclusion

Mineralization is a key process in industrial water and wastewater technology that ensures the efficient removal of organic pollutants and the stabilization of wastewater. The choice between biological and chemical processes depends on the specific requirements, such as the load of the wastewater, the availability of electron acceptors and the economic framework conditions. Modern technologies often combine both approaches to achieve maximum efficiency and provide sustainable solutions for water treatment.

For further information on our products, please feel free to contact us at any time!