Flocculants are essential chemical additives in industrial wastewater treatment that support the flocculation process by aggregating finely dispersed particles in the water into larger flocs. These larger flocs can be more easily separated by CP (sedimentation ) or flotation plants and contribute significantly to improving solids separation and compliance with legal limits. The effectiveness of flocculants depends on the composition of the wastewater and the specific properties of the particles. Flocculants are therefore available in different forms and with specific properties that are suitable for various industrial applications.

Table of contents

Technical background to flocculation

The flocculation process consists of two main phases:

- Coagulation: By adding precipitants such as iron or aluminium salts, the dissolved substances are destabilized and the finest particles are converted into the smallest flocs (primary flocs) by ion accumulation or chemical bonding.

- Flocculation: The primary flocs are aggregated by flocculants to form larger, more stable flocs, which can then be effectively separated by mechanical processes.

Types of flocculants and their functions

Anionic polymers

- Properties and function: Anionic flocculants carry negative charges and are therefore particularly suitable for flocculating particles with a positive charge. They act primarily by bridging between the particles and improve the agglomeration of the primary flocs.

- Areas of application: Anionic polymers are widely used in wastewater treatment in the food and beverage industry, in the paper and pulp industry and in the textile industry. They support the separation of organic substances and facilitate the removal of solids.

Cationic polymers

- Properties and function: Cationic flocculants have positive charges and are ideal for treating negatively charged particles. Due to the electrostatic attraction, they combine with the particles in the wastewater, which leads to the formation of larger and more stable flocs.

- Areas of application: These flocculants are frequently used in the metal processing and electroplating industries as well as in sludge treatment, where the removal of heavy metals and inorganic substances is the main focus.

Non-ionic polymers

- Properties and function: Non-ionic flocculants do not carry an electrical charge and are therefore particularly suitable for flocculation in wastewater with fluctuating pH values or particles that do not have a specific charge. Their effect is mainly based on bridging and physical attachment to particle surfaces.

- Areas of application: They are used in the petrochemical industry, paper production and in processes with high organic loads, as they offer a versatile solution for wastewater with different compositions.

Organic flocculants (polyacrylamides)

- Properties and function: Polyacrylamides are synthetic polymers that are available in various ionic forms (anionic, cationic and non-ionic). They offer high flexibility in application and are particularly effective in the formation of large, stable flocs by bridge flocculation.

- Applications: They are used in many industries, including food processing, chemical industry and mining. Polyacrylamides offer efficient flocculation with low chemical consumption and are suitable for wastewater with a high solids content.

Inorganic flocculants

- Properties and function: These include precipitants such as ferric chloride, aluminum sulfate and lime, which are used not only for coagulation but also as flocculants. Inorganic flocculants increase the density of the flocs and improve the sedimentation and filtration properties.

- Areas of application: They are often used in phosphate elimination in the food industry and in the removal of heavy metals in electroplating, as they bind poorly soluble solids and promote the settling of flocs.

Organic, natural flocculants

- Properties and function: These flocculants, such as chitosan and guar gum, are biodegradable and sustainable. They have good flocculation properties and are used in special environmentally friendly applications.

- Areas of application: These natural flocculants are particularly popular in the food industry and in the treatment of drinking water, as they are more environmentally friendly and less toxic than synthetic alternatives.

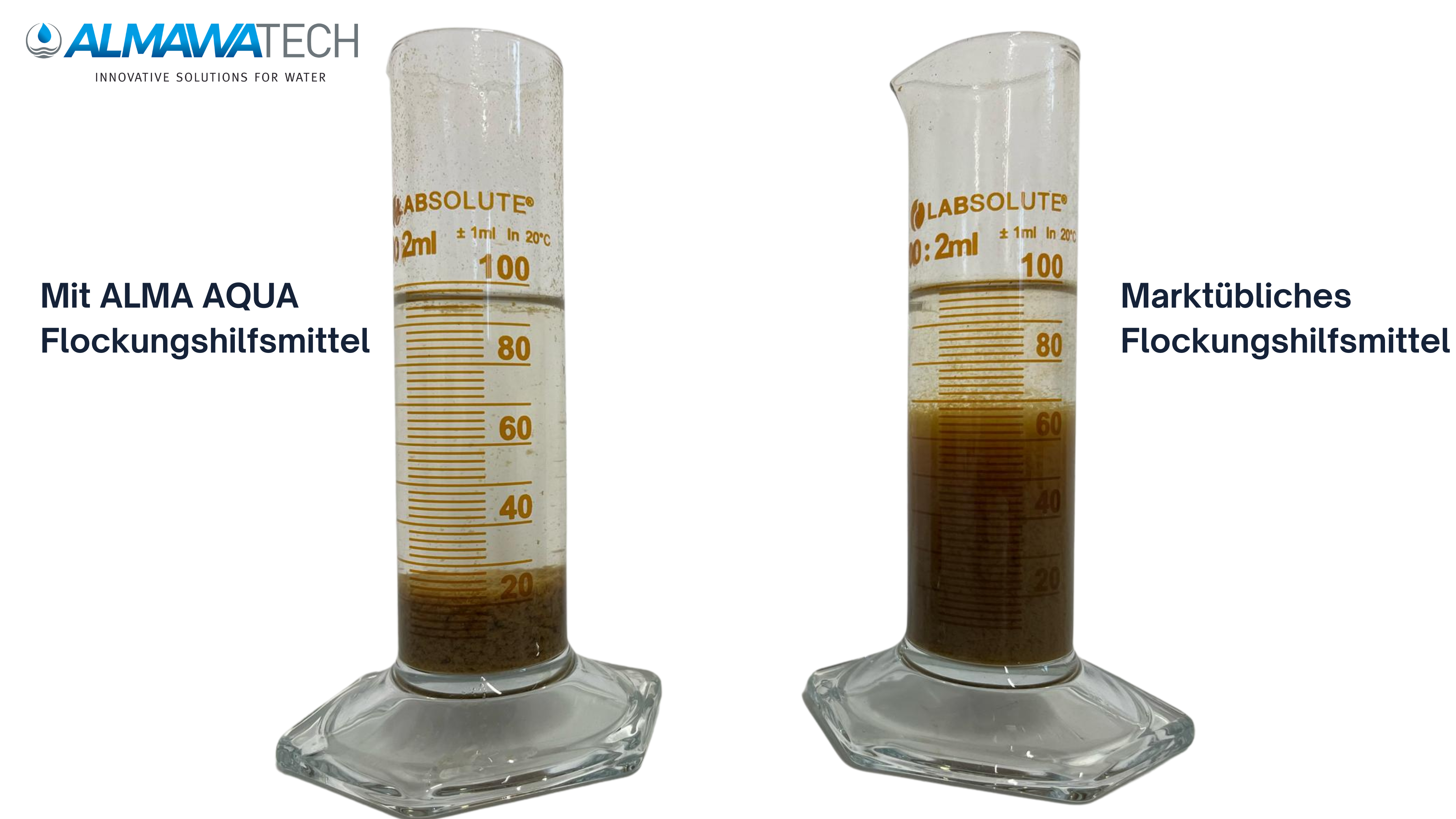

Photo: Comparison between a commercially available flocculant and a flocculant from the ALMA AQUA wastewater program

Application and function of flocculants in practice

In practice, flocculants are often dosed into the wastewater directly after the addition of precipitants. They ensure that the primary flocs combine to form larger flocs through polymer bridging or electrostatic interactions. Flocculants are usually dosed in a reaction tank with agitators or in turbulent flow pipelines to ensure even distribution in the wastewater and to create optimum conditions for floc formation.

The selection of a suitable flocculant depends on several factors:

- Type and charge of the particles: Depending on the chemical nature and charge of the particles in the wastewater, an anionic, cationic or non-ionic flocculant is selected.

- pH value: The pH value of the wastewater significantly influences the effectiveness of the flocculants, as the electrostatic interaction varies at different pH values.

- Solids concentration: Flocculants are particularly effective at higher solids contents, as they support the sedimentation and flotation of large flocs and improve the efficiency of wastewater treatment.

Advantages and challenges of using flocculants

Advantages:

- Flocculants increase the settleability and filterability of solids, which increases the efficiency of wastewater treatment.

- They are available in different chemical compositions, which allows them to be adapted to different wastewater.

- The use of flocculants reduces the consumption of chemicals in wastewater treatment and improves water quality through more efficient solids separation.

Challenges:

- The correct selection and dosage is crucial, as overdosing can lead to a deterioration in wastewater quality and increase costs.

- The efficiency of flocculants can be limited by high organic loads or extreme pH values, which requires precise adjustment.

Photo: Automatic dosing and preparation station for flocculant ALMA Floc AC with a treatment capacity of up to 2,000 l/h

Flocculants from ALMAWATECH

As a specialist in industrial wastewater treatment, ALMAWATECH offers a comprehensive range of flocculants in our product line ALMA AQUA Wastewater. Our flocculants include a variety of anionic, cationic and non-ionic polymers as well as organic and inorganic flocculants that are specifically tailored to the requirements of our customers. Our team of experts will be happy to analyze and test your wastewater in the laboratory to develop the optimal flocculation solution for your specific requirements. Through these tailor-made solutions, we maximize the efficiency of your wastewater treatment processes and help reduce operating costs.

Photo: ALMA AQUA Abwasser, send us your wastewater and we will find the optimum flocculant for you

Conclusion

Flocculants are indispensable components in modern wastewater treatment and enable the efficient removal of solids and impurities. With a wide selection of anionic, cationic and non-ionic polymers as well as organic and inorganic flocculants, wastewater treatment can be tailored precisely to the individual requirements of each industry. Through the targeted use of the right flocculants, companies can not only ensure compliance with legal requirements, but also reduce operating costs and optimize the performance of their plants. ALMAWATECH offers customized solutions and a comprehensive product portfolio that is supplemented by laboratory analyses and application-specific advice to ensure maximum efficiency and sustainability in wastewater treatment.

For further information on our products, please feel free to contact us at any time!