Defoamers are chemical additives that are used in various industrial processes to prevent or reduce unwanted foam formation. Foam often forms in water-bearing systems when gas bubbles are stabilized by surface tension. This foam formation can disrupt processes, reduce the efficiency of systems and increase maintenance costs. In industrial water and wastewater treatment, the use of defoamers is therefore essential to ensure smooth and efficient operation.

Table of contents

Technical principles of foam formation

Foam is formed by the incorporation of gas bubbles in liquids that are stabilized by surfactants or organic impurities. These substances reduce the surface tension of the water and promote the formation of stable layers of gas bubbles that remain on the surface of the liquid.

Foaming can occur in:

- Biological clarification stages: Here, the activities of microorganisms lead to the release of gases such as CO₂ and methane, which can cause foaming.

- cooling circuits: Due to high flow velocities and chemical impurities.

- Chemical reactors: For exothermic reactions, especially in the polymer and food industries.

Types of defoamers

Silicone-based defoamers

These defoamers contain silicone oils and are particularly effective in the treatment of organic foams.- Advantage: High efficiency with low dosages.

- Areas of application: Biological wastewater treatment and chemical processes.

Oil-based defoamers

Made from mineral oils or vegetable oils.- Advantage: Effective at high temperatures and heavily contaminated media.

- Areas of application: Petrochemicals, paper industry.

Water-based defoamers

Consist of emulsions and are more environmentally friendly.- Areas of application: Environmentally friendly systems, food processing.

Powdered defoamers

Are used in dry or powdery production processes.- Areas of application: Food and beverage industry.

Areas of application

Industrial wastewater treatment

In biological treatment stages such as activated sludge or MBR systems, defoamers prevent foam formation and the associated process disruptions.Food and beverage industry

During processing and cleaning, defoamers prevent foaming, which could lead to contamination or production downtime.Pulp and paper industry

Minimization of foam problems during the processing of fibrous materials and chemical additives.Chemical industry

In chemical reactors, defoamers prevent production losses due to foam formation, especially in polymer reactors.

Defoamer in cooling water and boiler water treatment

In cooling water and boiler water circuits, problems often occur with foam caused by dissolved gases, organic substances or chemical reactions. Foam can impair heat transfer, reduce the efficiency of cooling systems and lead to unwanted pressure fluctuations in boiler systems. Defoamers ensure that these processes are stable and efficient by preventing or reducing the formation of foam.

- Cooling water treatment: Protects cooling towers and heat exchangers from foaming and deposits.

- Boiler water treatment: Prevents overheating and ensures smooth operation.

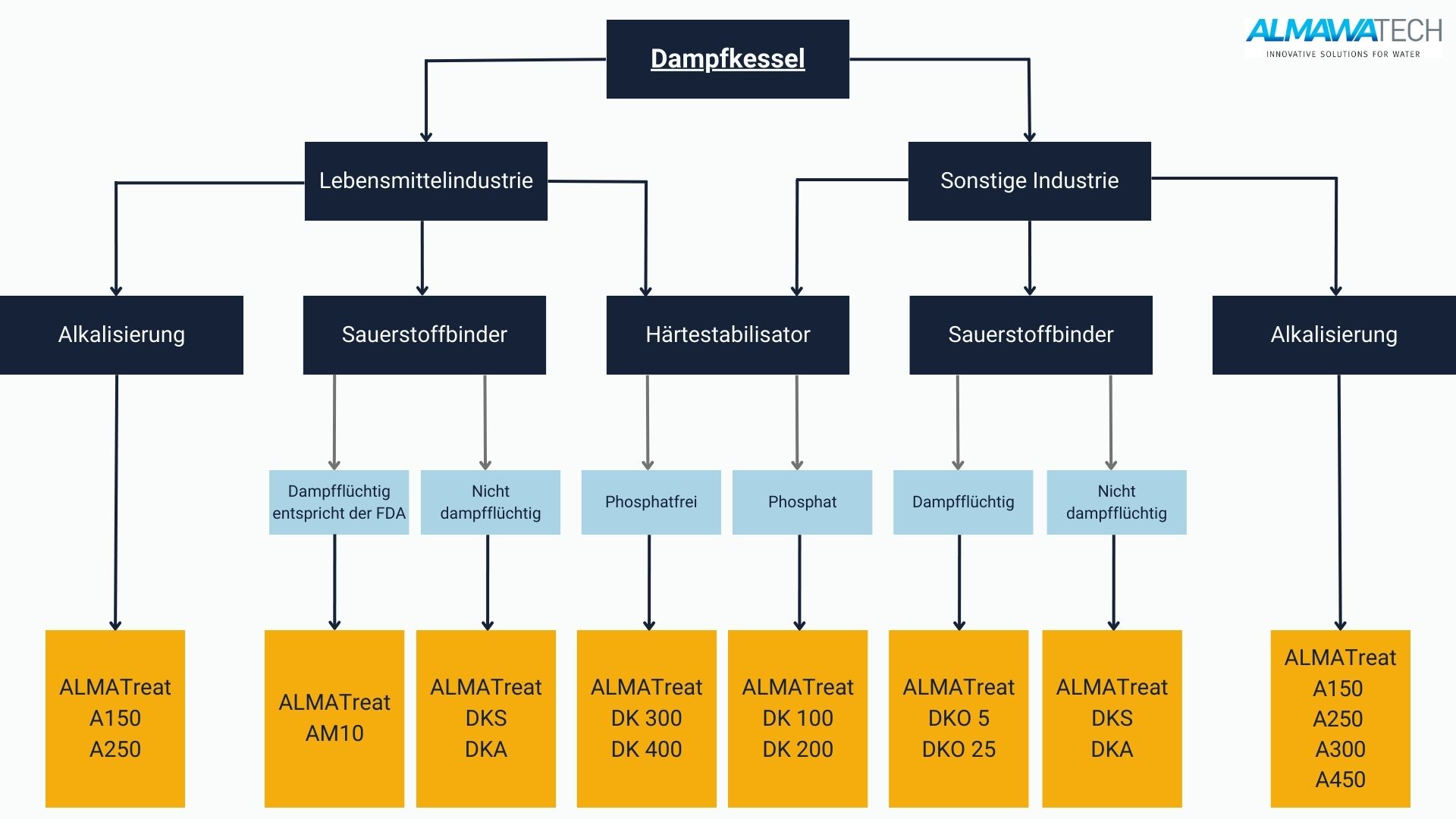

Photo: Product overview of various operating materials for steam boiler systems (ALMA AQUA boilers)

Our defoamers: ALMA AQUA boiler and ALMA AQUA cooling water

ALMAWATECH offers the following product lines ALMA AQUA boilers and ALMA AQUA cooling water a wide range of customized defoamers. These products are specially adapted to the respective industry and application. Made in Germany, they guarantee high quality and reliability. Our defoamers help to optimize your processes by increasing efficiency and reducing operating costs.

Conclusion

Defoamers are essential additives in industrial water and wastewater treatment that contribute to the stability and efficiency of systems by preventing the formation of foam. ALMAWATECH offers specialized products and services that meet the requirements of a wide range of industries and enable optimal process control.

For further information on our products, please feel free to contact us at any time!