Dispersants are special chemicals that are used in water and wastewater treatment to improve the distribution of fine particles and sediments in a liquid and to prevent particles from clumping or flocculating. In industrial water technology and wastewater treatment, dispersants prevent the formation and deposition of solids on surfaces, which plays an important role in circulation systems, pipelines and heat exchangers. Their application is particularly relevant for cooling water treatment, boiler water treatment and for membrane-based water treatment systemsto reduce the risk of fouling and scaling.

Table of contents

Technical background and function of dispersants

Dispersants work by modifying the surface charge of particles or by forming an electrostatic protective film around the particles. This creates repulsive forces that prevent the particles from sticking to each other and combining to form larger aggregates. These mechanisms support the stable distribution of solids in the water and help to minimize deposits in water treatment plants.

Mechanisms of dispersion

Electrostatic stabilization:

- Dispersants influence the surface charge of the particles in the solution. This generated charge leads to electrostatic repulsion between the particles, which prevents clumping. This property is particularly important in order to avoid deposits in narrow flow areas.

Steric stabilization:

- Some dispersants accumulate in a layer around the particles and create a steric barrier that separates the particles from each other. This barrier prevents the particles from coming closer together and thus forming larger aggregates or deposits.

Change in the particle surface:

- Dispersants change the surface properties of the particles and make them more hydrophilic, which improves their distribution in the water. Especially in systems with hard water conditions, in which calcium and magnesium ions tend to precipitate, dispersants prevent these particles from reaching surfaces and settling.

Types of dispersants and their specific applications

Dispersants can be divided into different categories depending on the type of water treatment and the chemical structure:

Anionic dispersing agents:

- Anionic dispersants have a negative charge and are suitable for stabilizing particles that have a positive surface charge. They are often used in cooling systems and in boiler water treatment to prevent the formation of calcium carbonate and magnesium deposits.

Cationic dispersants:

- These positively charged dispersants are used in applications where the particles have a negative charge. In wastewater treatment, cationic dispersants can be helpful in preventing floc formation in the treatment of industrial wastewater.

Non-ionic dispersing agents:

- Non-ionic dispersants have no charge and are stable in a wide range of pH conditions. These dispersants are useful for applications where the particle surfaces have different charges or the pH varies widely. They are widely used in membrane systems where the water composition is variable.

Polymer-based dispersants:

- Polymeric dispersants, such as polyacrylates and polyphosphates, have long molecular chains that wrap around the particles and create steric hindrances. They are particularly effective against calcium and magnesium deposits and are well suited for cooling and boiler water treatments.

Applications of dispersants in practice

Dispersants play an important role in various industrial water treatment processes to improve the efficiency of the systems and minimize the risk of deposits and fouling.

Cooling water treatment:

- Dispersants are used in open and closed cooling systems to prevent the build-up of calcium carbonate, magnesium salts and other mineral solids. The addition of dispersants keeps the cooling water clear and maintains heat transfer efficiency, reducing operating costs and extending system life.

Boiler water treatment:

- In boiler systems, dispersants prevent the formation of deposits on heat exchangers and heating surfaces, which would impair heat transfer. Especially in systems with hard water, where calcium and magnesium ions tend to precipitate, dispersants are essential to maximize boiler performance and minimize downtime due to cleaning.

Membrane processes in water treatment:

- In reverse osmosis and ultrafiltration systems, dispersants prevent fouling of the membranes by solids and colloids. By using dispersants, the service life of the membranes can be extended as the risk of clogging and a reduction in the filtration rate is reduced. The dispersants often work synergistically with antiscalants.

Textile and dyeing industry:

- Textile processing and dyeing often produce waste water with high concentrations of solids, which can lead to deposits and discoloration. Dispersing agents prevent the formation of deposits and help to keep production facilities clean. They also help to ensure that dye particles remain dispersed in the water and are not deposited on machine surfaces.

Paper and pulp industry:

- In paper production, dispersants prevent the build-up of fillers, clay and fibers on machines and surfaces. This leads to more efficient production, reduces maintenance and minimizes downtime.

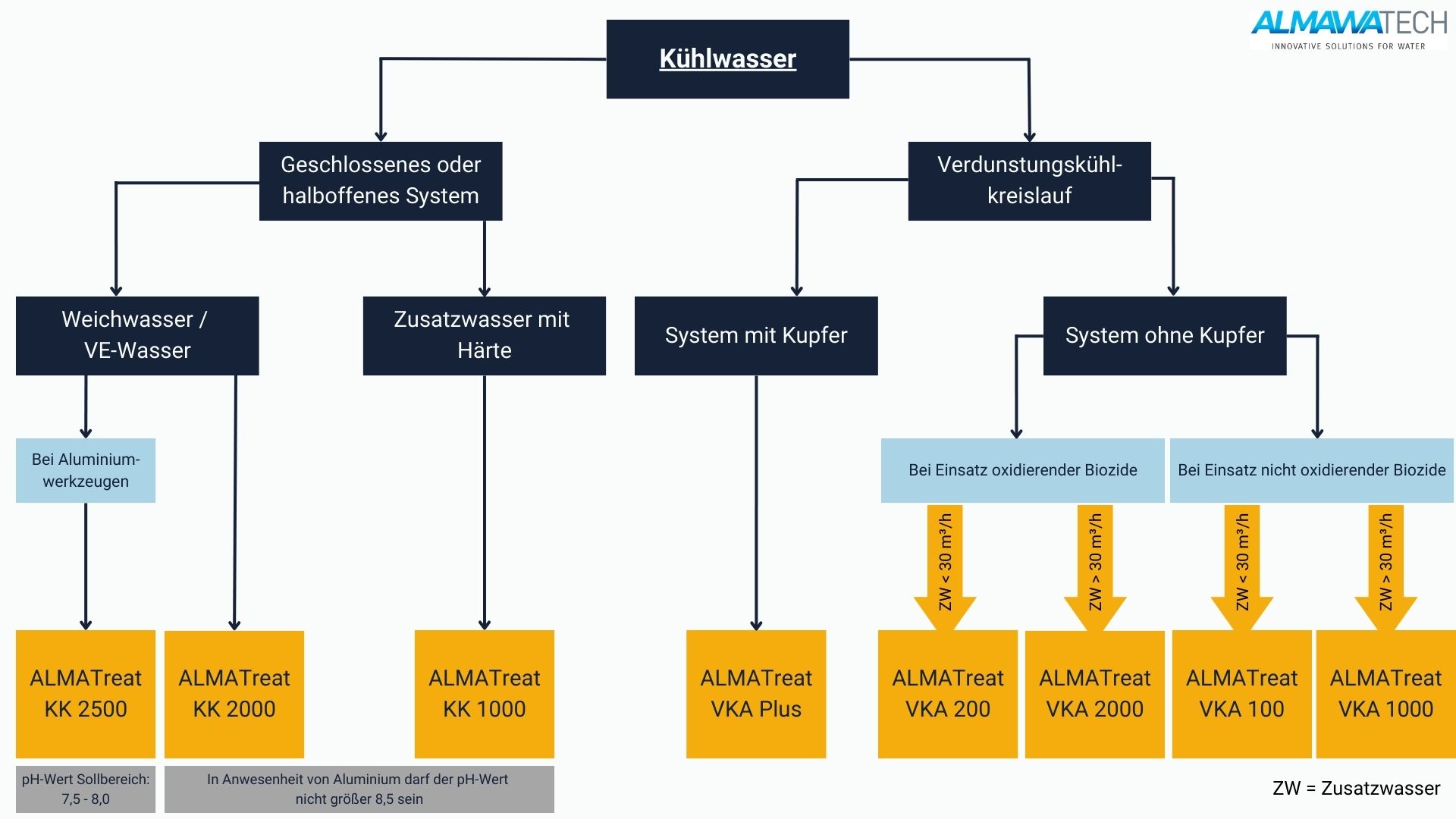

Photo: Product overview of some operating fluids for cooling water systems from the ALMA AQUA cooling water product range

Advantages and challenges of using dispersants

Advantages:

- Improved efficiency of water treatment: dispersants prevent deposits and fouling, thereby maintaining the efficiency and service life of water treatment systems.

- Reduced operating costs: Continuous dispersion reduces the need for frequent cleaning and maintenance, which lowers operating costs.

- Wide range of applications: Dispersants are customizable for many applications and can be adjusted to different water conditions and solid types.

Challenges:

- Optimizing the dosage: Precise dosing is important to ensure sufficient dispersion. Overdosing can lead to instability, while underdosing reduces the effect of the dispersants.

- pH and temperature dependence: The effectiveness of dispersants can vary at certain pH values and temperatures, which requires adaptation to specific process conditions.

- Compatibility with other chemicals: In many industrial applications, several water treatment agents are used simultaneously. Dispersants must therefore be compatible with other chemicals such as corrosion inhibitors and antiscalants in order to achieve an optimum overall effect.

Dispersants at ALMAWATECH: ALMA AQUA membrane, cooling water & boiler

ALMAWATECH offers a wide range of dispersants especially for the requirements of industrial water and wastewater treatment. Our ALMA AQUA Membrane, ALMA AQUA Cooling Water and ALMA AQUA Boiler-product line includes a selection of dispersants specifically formulated for applications such as cooling systems, boiler systems and membrane processes. With our tailor-made solutions, we ensure that your systems remain free of deposits and fouling, maximizing the efficiency and uptime of your equipment. ALMAWATECH also offers comprehensive laboratory analysis to find the optimum dispersant solution and dosage for your specific requirements.

Photo: Application-specific operating resources ALMA AQUA membrane, cooling water & boiler

Conclusion

Dispersants are indispensable components in industrial water and wastewater treatment. They prevent deposits, fouling and scaling in water treatment plants and ensure efficient and long-lasting system performance. With customized dispersants, such as those offered by ALMAWATECH in the ALMA AQUA Membrane, Cooling Water & Boiler line, plant operators can optimally protect their systems and significantly reduce maintenance and operating costs.

For further information on our products, please feel free to contact us at any time!