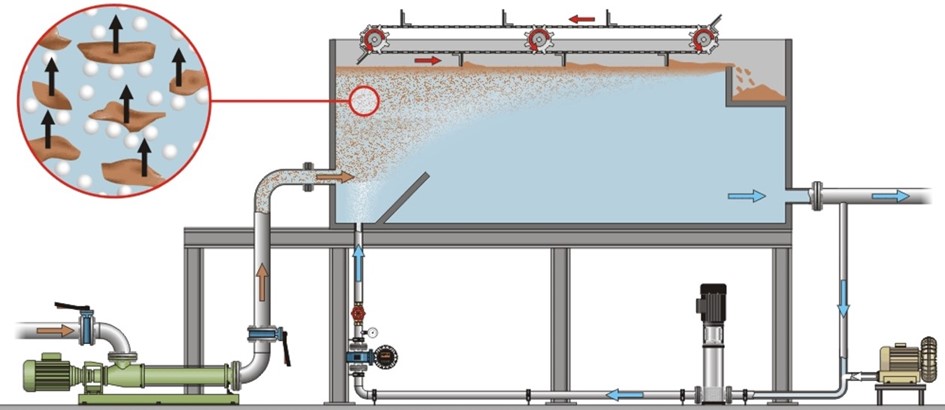

Dissolved Air Flotation (DAF) is a physical separation process widely used in industrial wastewater treatment to remove undissolved and dissolved substances such as fats, oils, hydrocarbons, dissolved metals and organic compounds (COD) from wastewater. The process combines chemical pre-treatment with a physical flotation technique to enable efficient separation of pollutants.

Table of contents

How dissolved air flotation works

The process begins with neutralization precipitation, in which dissolved substances are converted into undissolved particles. This is achieved by adding chemical treatment agents such as precipitants, neutralizing agents and flocculants, which are dosed into the wastewater in a targeted manner. The chemical pre-treatment leads to the formation of flocs that trap the pollutants. In the next step, these flocs must be physically removed from the wastewater.

As soon as the wastewater reaches the flotation cell, a second stream of water is introduced. This consists of clearly treated water that has previously been saturated with air under high pressure (4-6 bar). As soon as this saturated water flow is introduced into the flotation cell, the excess air bubbles up in the form of microbubbles (60-80 µm in diameter).

Microbubble formation and flotation sludge

The microbubbles are one of the main factors for the successful operation of a DAF. They enclose the previously precipitated undissolved particles and allow them to rise to the surface. This process leads to the formation of a flotate sludge on the water surface, which is then separated using a sludge scraper.

The efficiency of this process depends largely on the bubble size. Bubbles that are too large rise more slowly and have less adhesion to the contaminants, while bubbles that are too small can lead to overlapping, which disrupts floc formation. To ensure optimum flotation, the bubble size should be between 60 and 80 µm.

The bubble size is influenced by several factors:

- pH value of the wastewater

- Saturation pressure

- Flow velocity

- Water composition

Photo: Simplified process diagram of a DAF

Chemical control and dosing

A decisive success factor in DAF is the precise dosing of precipitants and flocculants. Overdosing can lead to uneconomical operation, while underdosing jeopardizes compliance with legal purification targets. Our flotation systems are equipped with a patented COD control system that automatically adjusts the dosage to the organic load in the wastewater. This load-proportional dosing leads to considerable savings in operating resources compared to conventional flotation systems.

Advantages of ALMAWATECH dissolved air flotation

DAFs from ALMAWATECH offer several technical advantages that guarantee high efficiency and operational reliability:

Non-clogging expansion valves: The air-saturated water flow is mixed evenly through pneumatic valves that operate without clogging.

Patented, energy-efficient air saturation system: the Venturi effect efficiently mixes the air into the water, which reduces energy consumption.

Bubble Booster System: This patented system ensures energy-efficient micro-bubble formation and guarantees the optimum bubble size to maximize floc formation and separation of pollutants.

Load-proportional dosing of operating agents: The inline dosing in our plants is controlled by a COD online measurement system that precisely adjusts the precipitants and flocculants to the wastewater load. This leads to considerable savings in operating costs.

Aerophilic floc formation: The return flow of the air-saturated water stream into the flocculation reactor promotes the formation of aerophilic flocs, which have better buoyancy and reach the surface more quickly.

All of our dissolved air flotation systems are equipped with an integrated process control system based on the ALMA Vision software in the Siemens TIA portal, as well as specially developed ALMA AQUA equipment for precipitants, neutralizing agents and flocculants. The optimum equipment is selected following comprehensive laboratory testing in order to best meet the specific requirements of your wastewater.

Dissolved air flotation from ALMAWATECH

ALMAWATECH offers various DAF systems for different applications and capacities:

ALMA NeoDAF HDED

- Flow rate: 12-150 m³/h

- COD reduction: 50-80 %

- Connected load: 0.09-0.30 kW/m³

Photo: Our DAF ALMA NeoDAF HDED for large wastewater flows up to 150 m³/h

ALMA NeoDAF HD

- Flow rate: 8-27 m³/h

- COD reduction: 50-80 %

- Connected load: 2-5 kW

Photo: Our compact DAF ALMA NeoDAF HD for medium and highly contaminated wastewater.

ALMA NeoDAF Blue

- Flow rate: 1-7 m³/h

- COD reduction: 50-80 %

- Connected load: 2-4 kW

Photo: Our compact DAF ALMA NeoDAF Blue for small wastewater flows

Areas of application

The DAF is used in many industrial sectors, especially where the wastewater contains high concentrations of fats, oils, hydrocarbons or heavy metals. The technology is ideal for various industries that require effective wastewater treatment:

- Food and beverage industry: Removal of fats, oils and organic substances from production waste, especially in dairies, where wastewater is characterized by high organic loads.

- Plastics processing: Separation of organic substances, AOX and residual particles from process wastewater.

- Metal processing: Efficient separation of dissolved metals, heavy metals, oils and greases from industrial wastewater.

- Recycling industry: Removal of hydrocarbons, fats and poorly degradable organic compounds from wastewater.

- Petrochemicals: Reduction of hydrocarbons and other chemical compounds from highly contaminated wastewater.

- Tank cleaning: Cleaning of waste water containing residues of hydrocarbons and chemicals.

- Surface waters: treatment of surface waters such as rivers or lakes to reduce phosphates and nitrogen

Photo: DAF ALMA NeoDAF HDED for the treatment of dairy wastewater

Conclusion

The DAF is a powerful method for separating pollutants from industrial wastewater. With ALMAWATECH's specially developed technologies, such as the Bubble Booster System and COD-controlled dosing, our customers can not only optimize purification performance, but also achieve significant savings in operating costs. Our flotation systems, including the NeoDAF HDED, NeoDAF HD and NeoDAF Blueoffer customized solutions for a wide range of industrial applications.