Cationic polymer is an essential component in industrial water and wastewater treatment, which is mainly used as a flocculant. flocculant used as flocculants. These polymers are positively charged (cationic) and their electrostatic attraction enables the formation of larger flocs that can be more easily separated from the water. Cationic polymers are particularly effective in the treatment of wastewater containing negatively charged particles or organic compounds, such as those frequently found in the paper industry, food processing and metalworking.

Table of contents

Technical background

Cationic polymers consist of long molecular chains to which cationic (positively charged) groups are attached. These groups attract negatively charged particles in the wastewater and neutralize their charge. This process leads to destabilization of the particles and bridging between the particles, resulting in the formation of larger flocs. These larger flocs either settle more quickly (sedimentation) or can be easily removed from the water by flotation systems or CP systems.

The efficiency of a cationic polymer depends on several factors:

- Charge density: The charge density of the polymer determines how strongly it attracts the particles and how effective the floc formation is. Cationic polymers with a high charge density are particularly effective with heavily contaminated wastewater, whereas polymers with a low charge density are often suitable for milder applications.

- Molecular weight: The molecular weight influences the structure of the flakes. Higher molecular weight cationic polymers lead to the formation of larger and more stable flocs, which are ideal for applications with a high solids content.

- pH range: The effectiveness of cationic polymers can depend on the pH value of the wastewater. However, they are usually active in a wide pH range (neutral to slightly acidic), which allows them to be used in a wide variety of wastewaters.

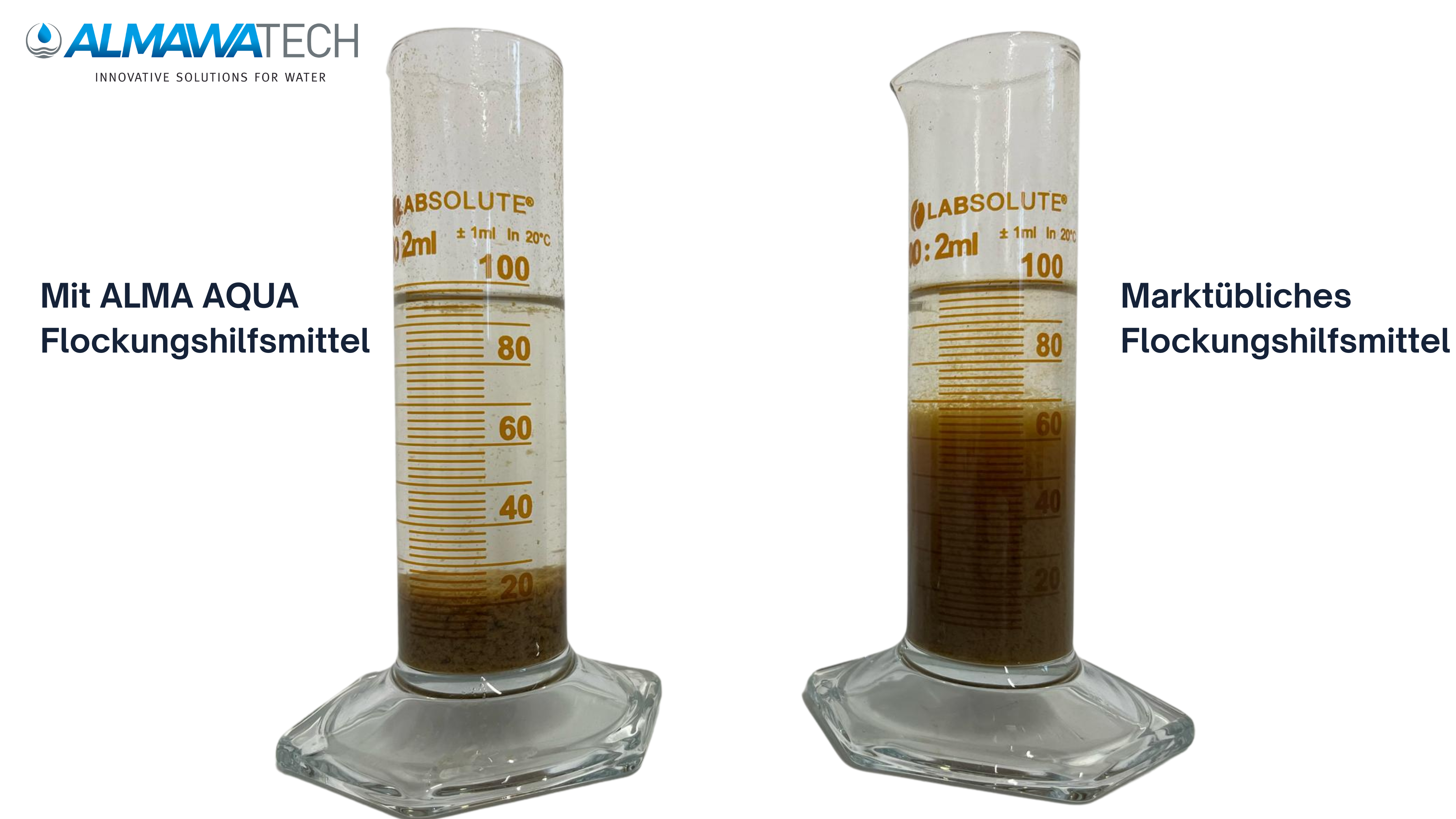

Photo: Comparison between a polymer (flocculant) from ALMAWATECH and a commercially available polymer ( ALMA AQUA Wastewater product overview)

Types of cationic polymers and their applications

Polyquats (polyquaternary ammonium compounds):

- Properties and function: Polyquats are synthetic polymers with a high cationic charge density. They are particularly effective in removing organic substances and anionic (negatively charged) particles.

- Areas of application: Polyquats are used in the paper industry to remove organic material in wastewater and improve clarification. They are also used in the food processing and textile industries to separate fine particles.

Polyacrylamide (PAM):

- Properties and function: Polyacrylamides are versatile polymers that are available in cationic, anionic and non-ionic form. The cationic variant is mainly used for flocculation and solids separation. They work by electrostatic attraction and bridging between the particles.

- Areas of application: Cationic polyacrylamides are widely used in sludge conditioning and are used for the treatment of industrial starches and wastewater, as they provide very strong flocculation at a low dosage.

Diallyldimethylammonium chloride (DADMAC)-based polymers:

- Properties and function: These polymers are characterized by high resistance and effectiveness at low dosage. They are highly soluble in water and stable at a wide range of pH values.

- Areas of application: DADMAC-based polymers are often used in the metalworking and oil and gas industries, where they are used to remove particles and emulsions from wastewater.

Biodegradable cationic polymers:

- Properties and function: These polymers are environmentally friendly alternatives to conventional synthetic polymers. They are biodegradable and reduce the ecological footprint.

- Areas of application: They are increasingly used in the food industry and in the treatment of drinking water, where sustainability and environmental compatibility play an important role.

Function and advantages of cationic polymers

The main function of cationic polymers is to facilitate the separation of solids and impurities in wastewater. Through electrostatic attraction and the formation of stable flocs, they significantly improve the settling rate and filterability of the solids. This brings numerous advantages:

- Improved wastewater quality: Cationic polymers increase the separation rate of particles and reduce suspended solids in the wastewater, resulting in higher clarity and quality of the treated water.

- Energy and cost efficiency: Due to the strong floc formation, cationic polymers can reduce the necessary sedimentation and filtration time, which lowers energy consumption and operating costs.

- Reduced chemical consumption: Effective floc formation means that the dosage of other chemicals, such as precipitants, can often be reduced, which also saves costs and reduces the environmental impact.

Challenges and optimal application

Although cationic polymers are versatile, there are some challenges in their application:

- Overdosing: Excessive dosing can have a negative impact on wastewater quality and reduce separation efficiency. Precise dosing and monitoring is therefore required.

- Sensitivity to temperature and pH: In some cases, the effectiveness of cationic polymers can be impaired by extreme pH values or high temperatures, which is why the process conditions must be closely monitored and controlled.

For optimal use of cationic polymers, various parameters such as dosing quantity, pH value and reaction time should be tested on a small scale in order to achieve the best flocculation results.

Photo: Automatic dosing and preparation station for polymer (flocculant) ALMA Floc AC with a treatment capacity of up to 2,000 l/h

Cationic polymers from ALMAWATECH

As a specialist in industrial wastewater treatment, ALMAWATECH offers a wide range of cationic polymers in our product line ALMA AQUA Wastewater product line. Our products include both synthetic and biodegradable variants that are specifically tailored to the needs of our customers in different industries. In order to find the best possible solution for your wastewater, we carry out laboratory analyses and test the wastewater to determine the most suitable cationic polymer and the optimum dosing quantities. This enables efficient and cost-effective wastewater treatment and ensures maximum separation performance while minimizing chemical consumption.

Photo: Cationic and anionic polymers from the ALMA AQUA wastewater series

Conclusion

Cationic polymers are indispensable flocculants used in a variety of industrial applications to improve wastewater treatment. Their positive charge and specific chemical structure enable the targeted aggregation and separation of negatively charged particles, which increases the efficiency of the entire clarification process. With ALMAWATECH's tailor-made solutions and comprehensive product range, we offer our customers the opportunity to optimize their wastewater treatment sustainably and cost-effectively.

For further information on our products, please feel free to contact us at any time!